Enterprise Story|The journey of 24 years, KJ CNC equipment high-end progression road

Time: Sep 05, 2022Views:

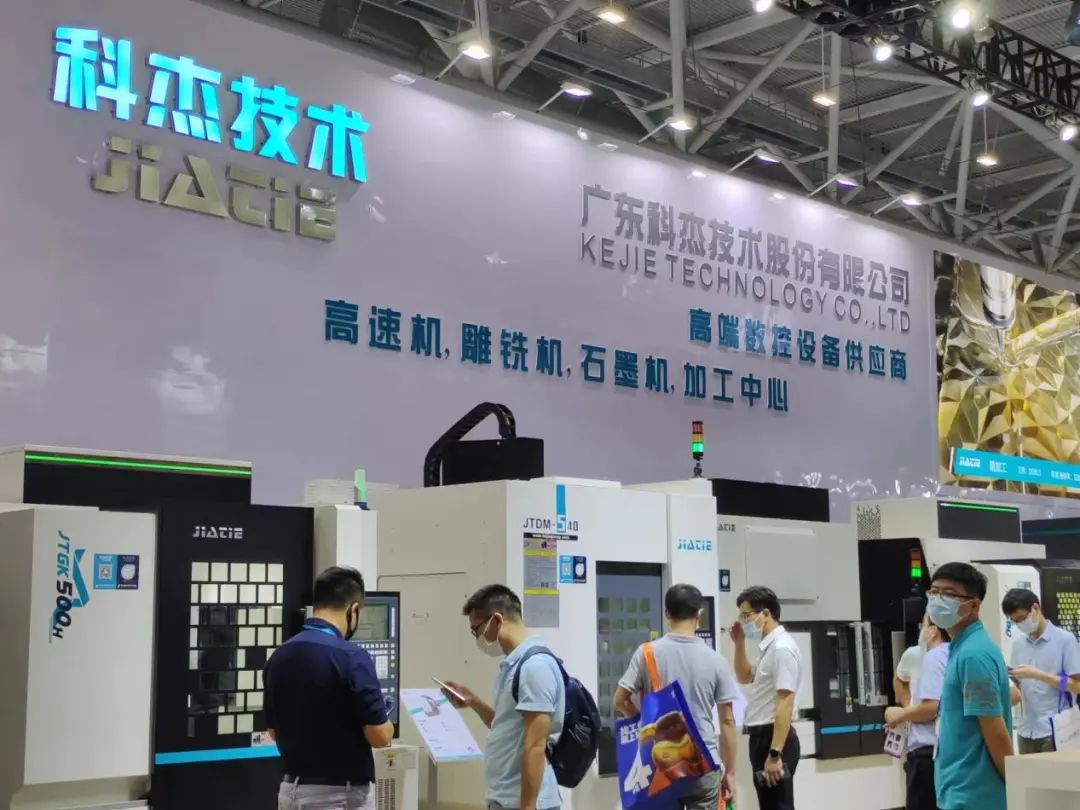

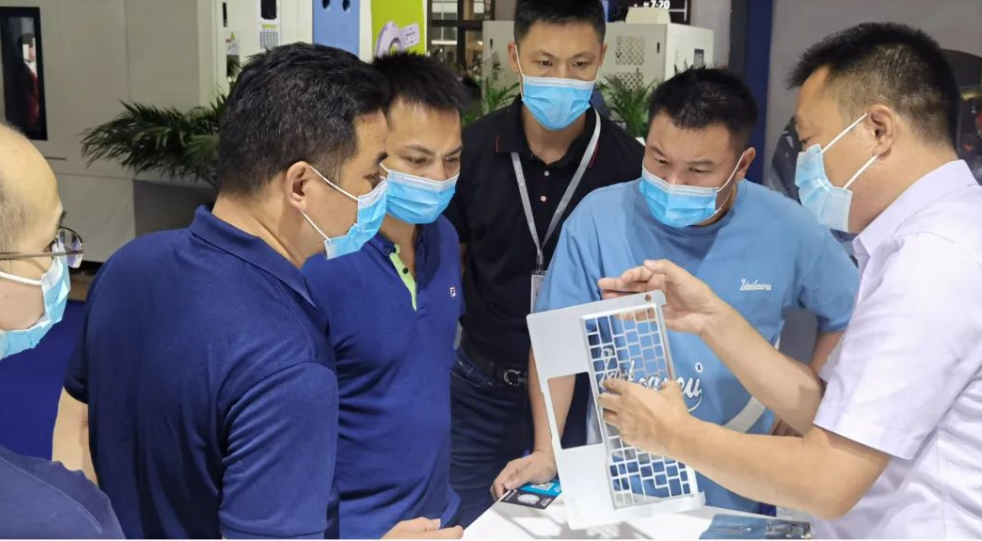

Perhaps due to the influence of the epidemic norm, the flow of people participating in the Shenzhen Industrial Exhibition in August this year was less than in previous years, but the booth of Guangdong Kejie Technology Company Limited ("Kejie") was still crowded with people and became the popular king of the whole venue.

According to the on-site observation of Chiu-Tech, Kejie exhibited a variety of high-end CNC equipment this year, including mold processing equipment, product processing equipment and automated intelligent silo three categories, involving applications mainly in mold electrodes, 3C products, new energy vehicles, home appliances, medical, etc.

Liu Chunsheng, deputy general manager of sales who has been working in Kejie for more than 20 years, has been active in the front line of the market for more than ten years and knows the industry pattern and customer demand very well. He said, "In the field of high-end CNC equipment, we are fully capable of making world-class national products, which is also the goal of the continuous joint efforts of Kejie and industrial chain partners."

Up to now, the cumulative sales of KJ's self-developed CNC systems have exceeded 60,000 sets. The products are not only used in batch in head manufacturing enterprises such as Lanshi Technology, Foxconn and Jabil Green Dot, but also are members of the first-class "fruit chain", and the market share of high-end equipment produced by Kejie is increasing year by year.

In addition, as a leading company in China's high-speed CNC engraving and milling machine industry, Kejie has grasped the market demand opportunity and quickly cut into the new energy vehicle track, becoming an important partner of BYD, the global leader of new energy vehicles.

Industry east wind to

According to the "Made in China 2025 Plan", by 2025, the domestic market share of China's high-grade CNC machine tools and basic manufacturing equipment will exceed 80%, and high-grade CNC machine tools and basic manufacturing equipment will enter the ranks of world powers in general.

For Kejie, with years of technical resources as the foundation, and with the east wind of industrial policy, its high-end dream has gradually shone into reality.

"Compared with the past, now the customer's requirements for equipment precision has increased significantly, long ago from the silk to μ level." Liu Chunsheng said, especially home appliances, automobiles, and 3C products such as cell phones and watches, whose shells and screens not only need precision, but also need to bring the end user aesthetics and touch multiple experiences.

Kejie technical team has fully mastered the development and mass production of CNC system, machine tool structure and core functional components and other key core technologies, CNC machine tools and automation equipment for cell phones and tablet PC cover glass, CNC high-speed machine for μ-level high-precision processing, environmental protection high-speed graphite machine and other products are to break the foreign monopoly, playing a strategic role of domestic alternative to imports.

Smart cars are considered to be the biggest windfall in the next decade, and its market size is estimated to be over 15 trillion yuan by Tide Electric Intelligence, and related industry chains are racing to enter this new track. For Cogent, it has also found the most suitable market demand fit.

Because of the different design scheme and new car-making concept, aluminum alloy materials are now more widely used in new energy vehicles, including key components such as bumper crash beams, battery packs, hydraulic boxes, in-car dashboard support frames, window frame load-bearing beams and rolling rail components.

"The precision requirements for the production of components for new energy vehicles and the high requirements for related CNC machine tool equipment have greatly extended the application scenarios of KJ's independently developed products, and is where our strength lies." According to Liu Chunsheng, the company has already started in-depth cooperation with BYD and other head enterprises in the field of new energy vehicles.

High-end is not just technology

At the exhibition site, KJ's positioning of "high-end CNC equipment supplier" shone on the whole scene.

"Breakthrough high-end, achieve high-end" is the gene that Kejie has carried since its establishment in 1998. From a small workshop more than 20 years ago, it has developed into a high-tech enterprise with nearly 1,000 professional talents today.

Nowadays, Kejie is the drafting unit of the national standard of "high-speed CNC engraving and milling machine". Its JTGK series high-speed CNC milling machines are recognized as high-tech products of Guangdong Province and exported to the United States, Germany, Britain, Japan and other industrial powers.

CNC machine tools, as "machines that make machines", are called "industrial mother machines" and are the most central link in the industrial manufacturing chain. Liu Chunsheng believes that high-end should first of all be the continuous advancement of technology, with continuous investment in research and development to provide users with cost-effective top products.

As of March this year, KJ has a R&D team of more than 230 people, accounting for 23.5% of the company's employees. The number of patents granted exceeds 200 and is still increasing at a rate of 10-20 per year, forming a strong patent moat. "Only when the core technology is in our own hands, we will not be 'necked' by foreign countries."

"Not only the products should be high-end, but also the services should be high-end." In Liu Chunsheng's view, compared to overseas strong players, Chinese enterprises in addition to the product and technology end to achieve catch-up, professional localization services are conducive to the formation of competitive advantage.

Scale, intelligence is an important feature of modern manufacturing enterprises, but the lack of professional talent is the industry's long-term difficulties and pain points. Take high-end CNC machine tools as an example, the product has been upgraded from three-axis to five-axis, if experienced personnel leave, the entire production chain is easy to fall into a state of gridlock.

For this reason, in the process of pre-importation of equipment, Kejie has formed a complete set of standardized processes, which not only allows customers to get up to speed quickly in terms of operation, but also does not affect production due to staff turnover.

"For customers, a good product must first be a good product to use." Liu Chunsheng said that the proportion of relevant professional technical service personnel of Kejie is more than 20%, which is already far ahead of overseas rivals in terms of response speed or providing added value to customers.

It is reported that Kejie's service network spreads to more than 40 regions and cities across China, and keeps good cooperation with many top 100 technology companies.

CNC machine tools are precise and complex machinery and equipment, often using hundreds of raw materials and components in production. Therefore Liu Chunsheng called on China to catch up with overseas in the process of high-end CNC equipment, the need for industry chain partners to unify communication protocols in an open stance, to improve data interaction and compatibility. "Everyone will be good at their own areas of excellence, you can quickly achieve a bend in the high-end market overtaking."

High-end set the future, the future has come. At the tip of the pyramid of CNC equipment, there will be more of these Chinese enterprise figures of KJ.

Translated with www.DeepL.com/Translator (free version)

recommend

Feb 03, 2024

Recently, overseas institutions have downgraded Apples rating. For a time, Apple from being bearish in mainland China du...

Hot