Introduction

ENPHASE ENERGY is a leading global manufacturer of microinverters, founded in 2006. Their flagship product is the IQ series of microinverters, and this disassembly focuses on the IQ7+, the seventh generation microinverter that supports up to 72 photovoltaic modules and delivers an output power of 290VA for distributed solar power generation. In addition to microinverters, ENPHASE also offers battery storage systems with built-in inverters, providing 220V AC output for residential power supply, and supports monitoring of solar system generation, storage, and usage through a mobile app, creating an all-in-one solution.

Let's now disassemble the IQ7+ microinverter to examine its internal components and operational principles.

ENPHASE IQ7+ Micro Inverter Exterior The ENPHASE IQ7+ microinverter features a housing made of PPE+PS plastic with a matte finish. It has fixed slots and output connection terminals on both sides.

On the front side, there is a product label with the following specifications: Power Factor Range: +/-0.8

Maximum DC Input: 60V

Maximum Input Short Circuit Current: 15A

Maximum Continuous Input Current: 12A

AC Output Voltage: 230V, Single-Phase

AC Output Current: 1.26A

AC Output Frequency: 50Hz

AC Output Power (Maximum Continuous Output): 290VA

Output Rating: IP67

The IQ7+ microinverter is CE certified.

The irregularly textured surfaces on both the front and back of the unit provide an industrial appearance.

One side of the unit includes three connection terminals and a status indicator.

The left side features DC input terminals, while the right side has AC output terminals.

A close-up of the status indicator.

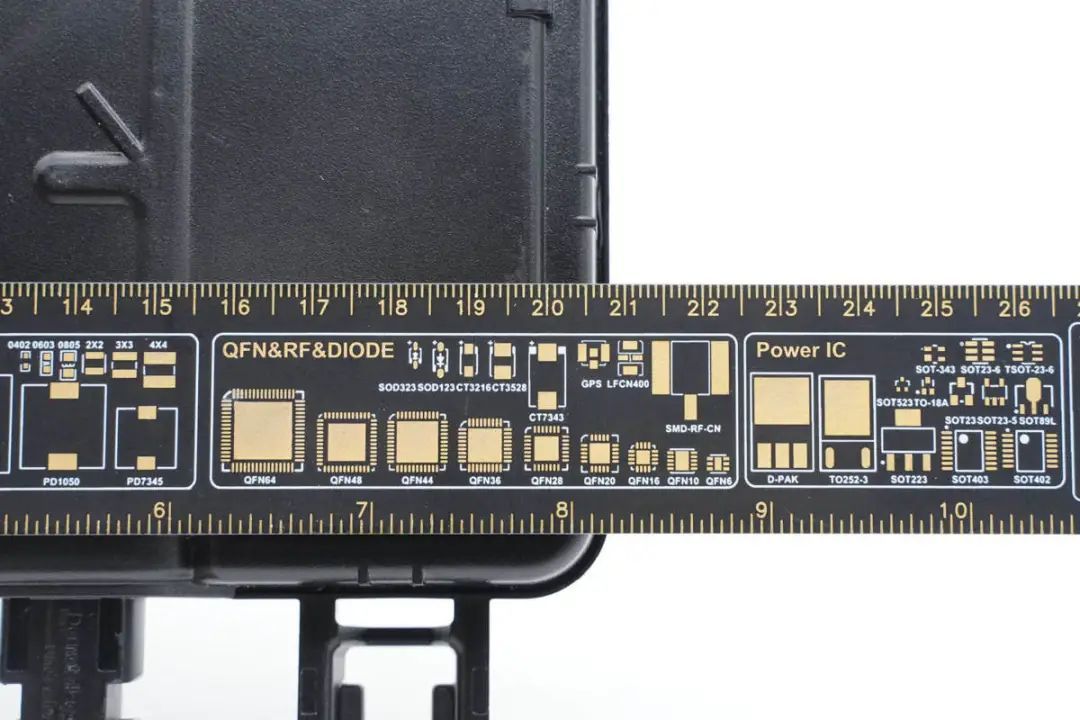

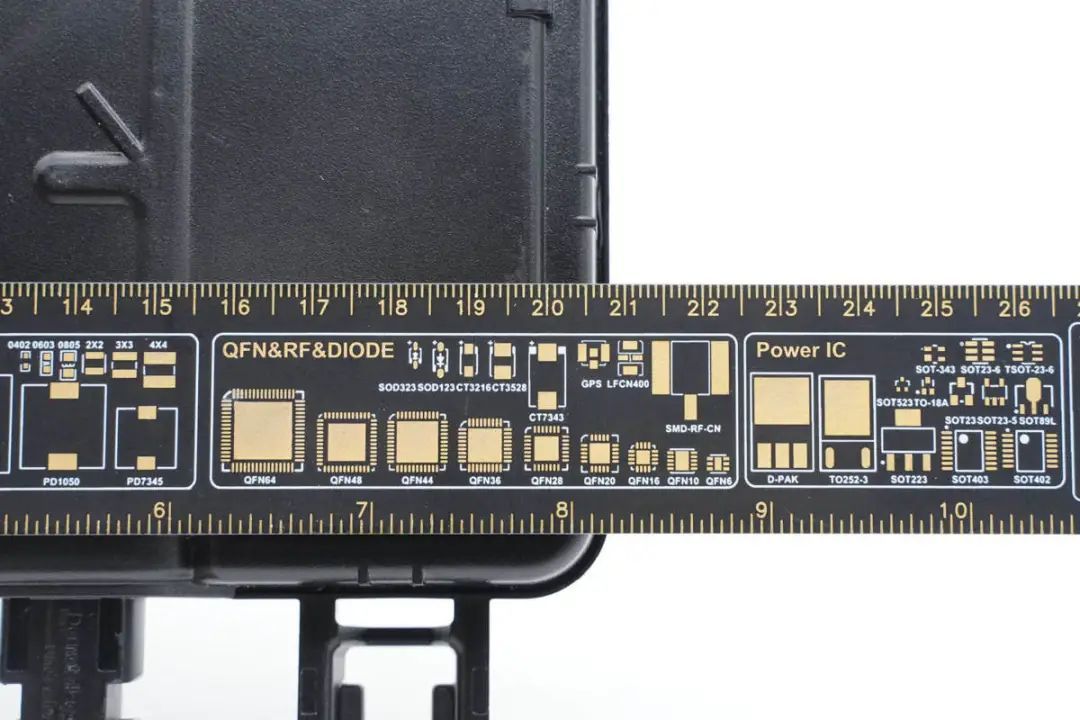

The main body of the unit measures approximately 20.8 cm in length.

The width is about 12.3 cm.

The thickness is approximately 3 cm.

The IQ7+ microinverter weighs around 938g.

Disassembly of ENPHASE IQ7+ Micro Inverter

Disassembly of ENPHASE IQ7+ Micro Inverter

Having examined the exterior, let's proceed with the disassembly to explore its internal design.

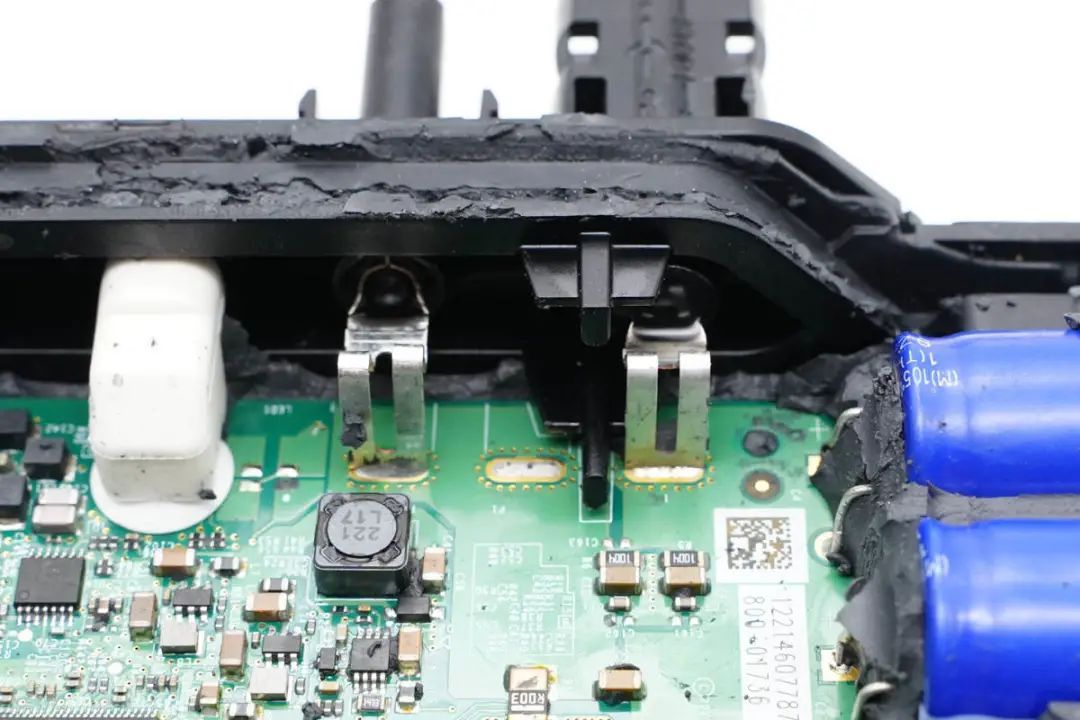

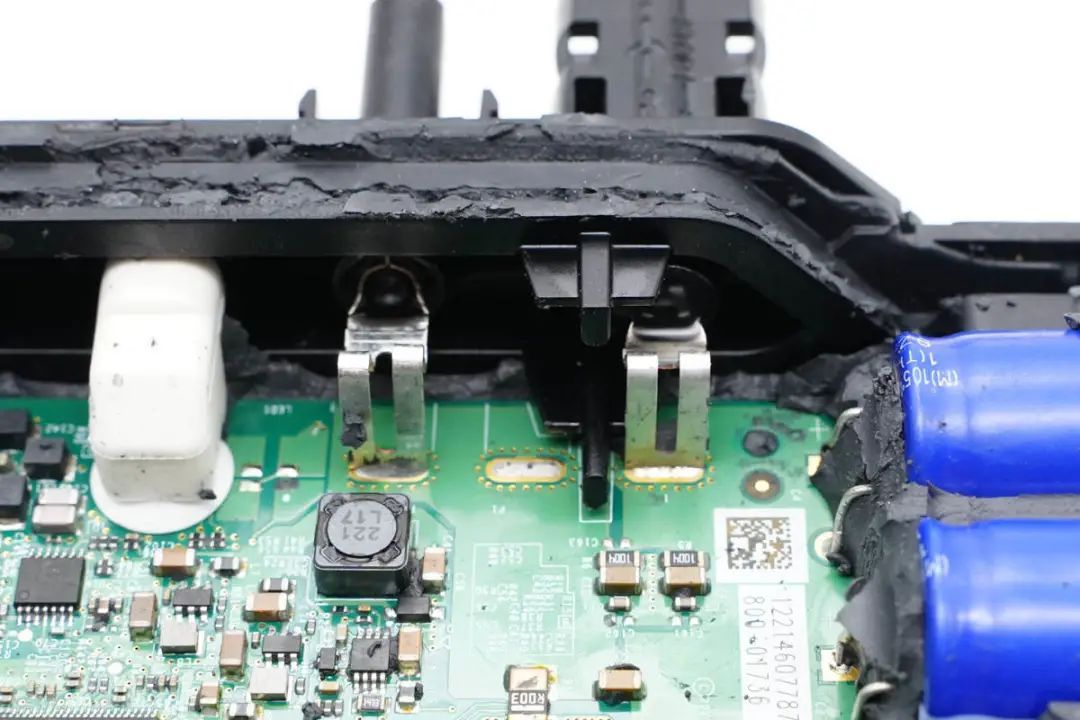

Using a heat gun and a pry bar to open the inverter's casing, we find the interior filled with thermal adhesive.

The thermal adhesive is elastic and fills the space effectively.

The shape of the adhesive conforms to the inside of the casing.

After cleaning the adhesive from inside the casing, the PCBA module is exposed.

A close-up of the DC positive and negative input terminals.

A close-up of the AC output terminals.

A close-up of the status indicator.

Disconnecting the terminals from the PCB, we remove the PCBA module from the casing.

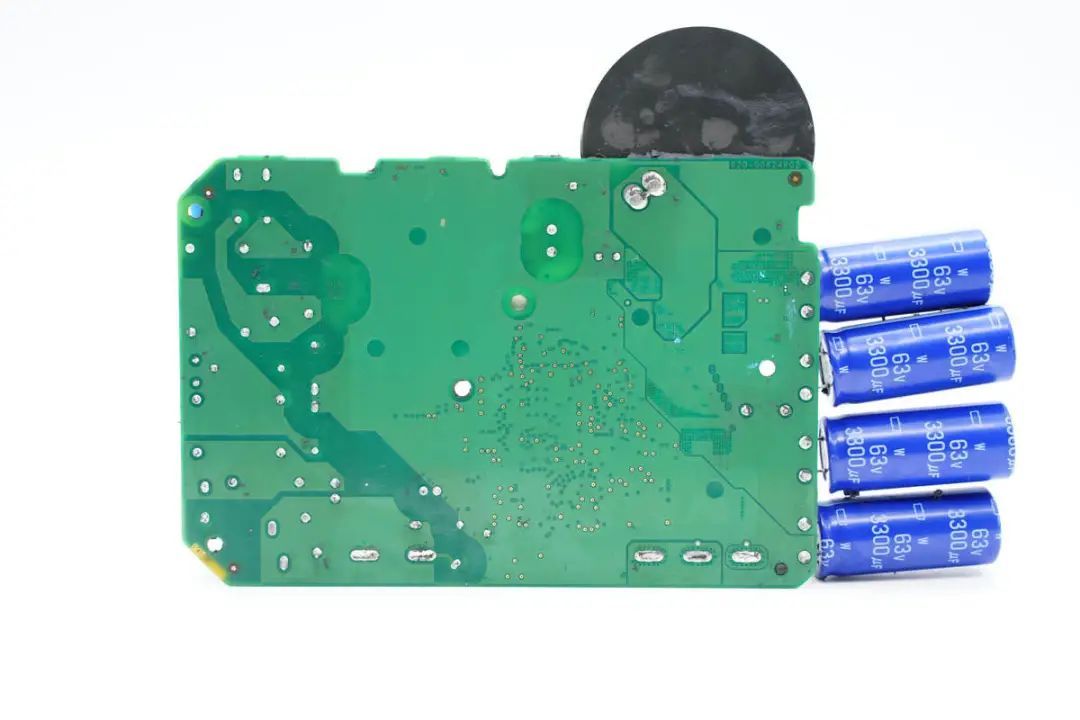

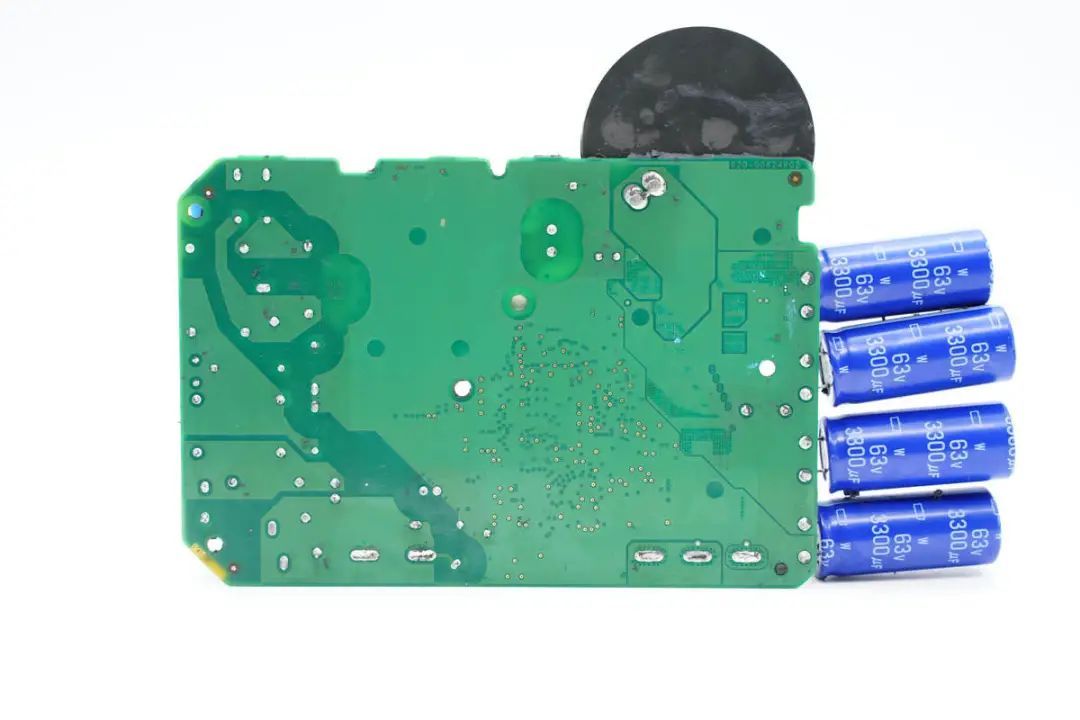

The back of the PCBA module features aluminum heat sinks attached, which provide heat dissipation for the boost power transistors and output modulation transistors.

Removing the heat sinks, blue thermal compound is applied to enhance heat dissipation at the locations of the boost power transistors and modulation transistors.

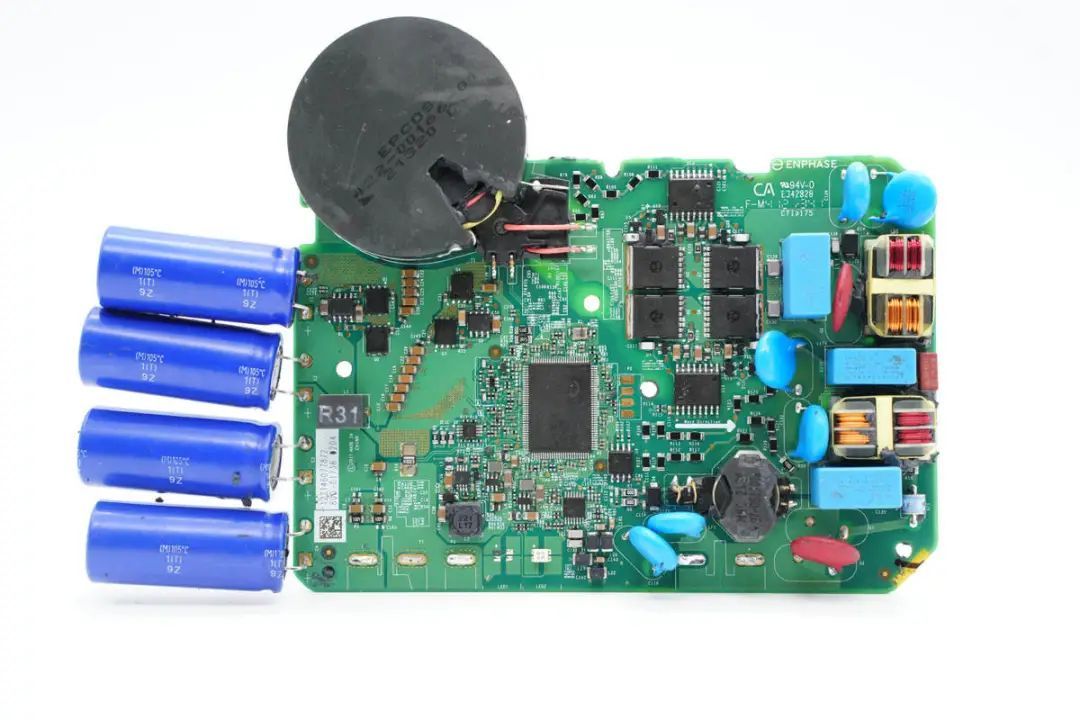

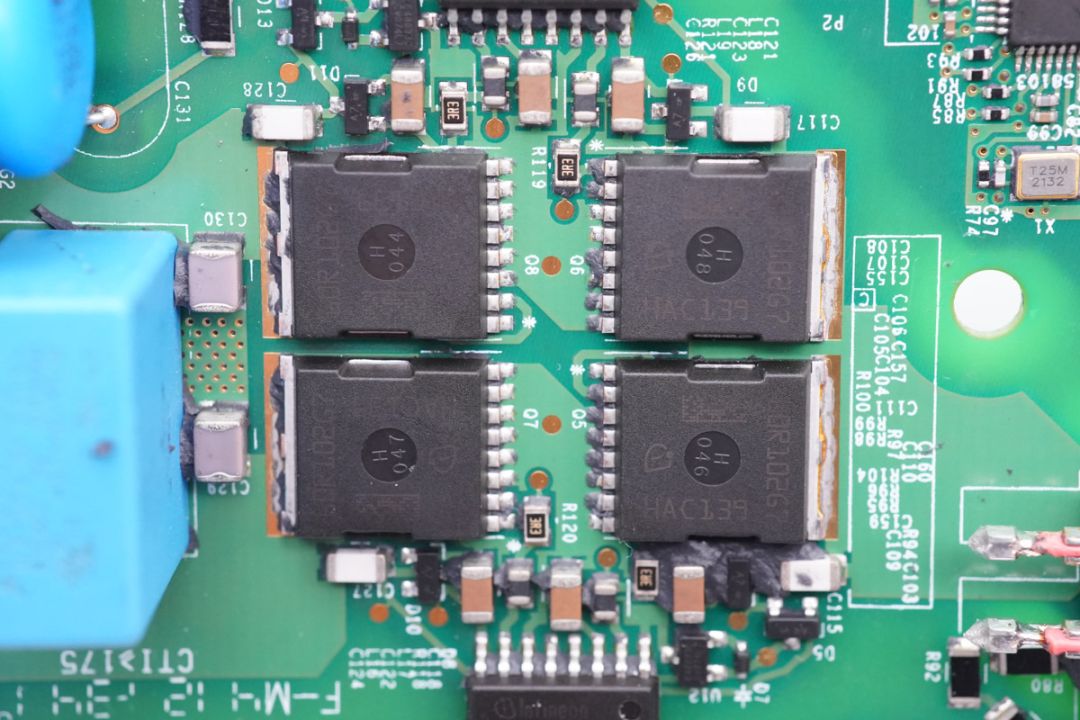

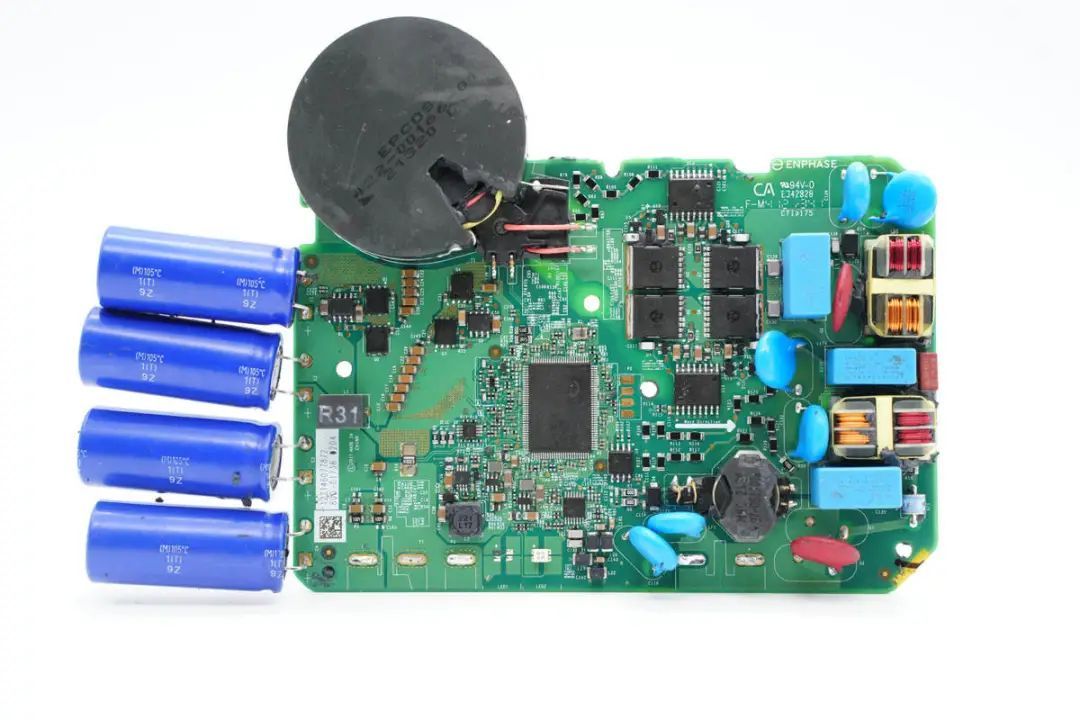

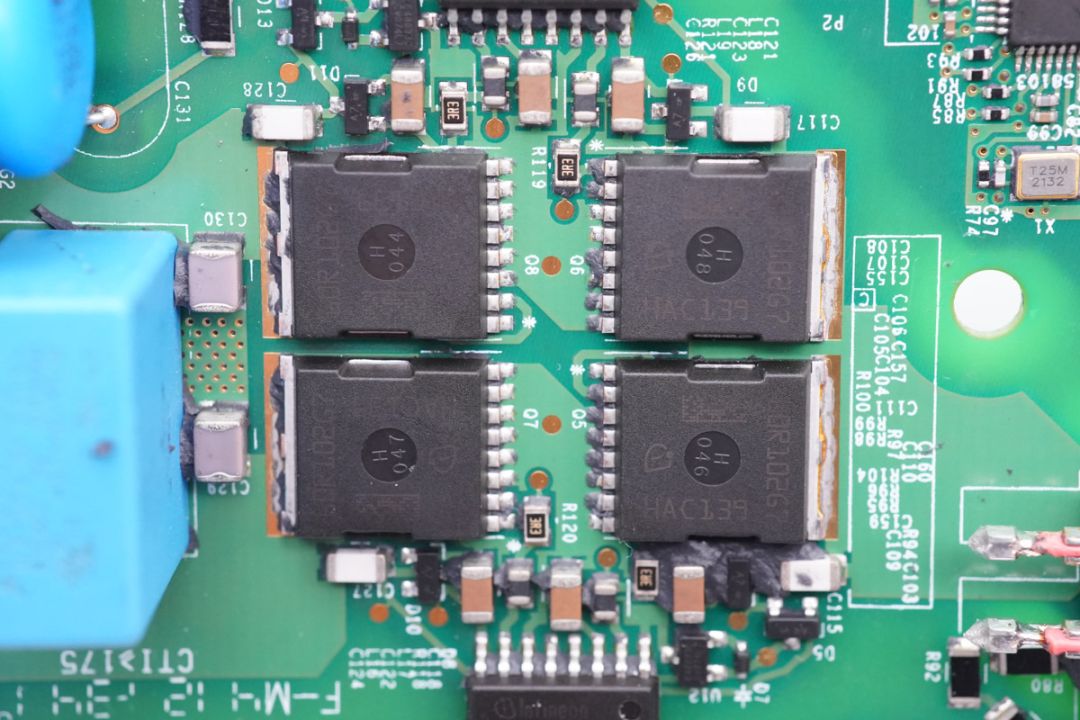

An overview of the front of the PCBA module shows input filter capacitors soldered on the left side. The upper part contains the inverter transformer, and the lower part features low-voltage MOSFETs for inversion and their corresponding drivers. The main control chip is located in the middle of the board, with four output modulation MOSFETs and their isolation drivers on the right side. The far right side contains filtering components.

The solder points for through-hole components are on the back, with no components present.

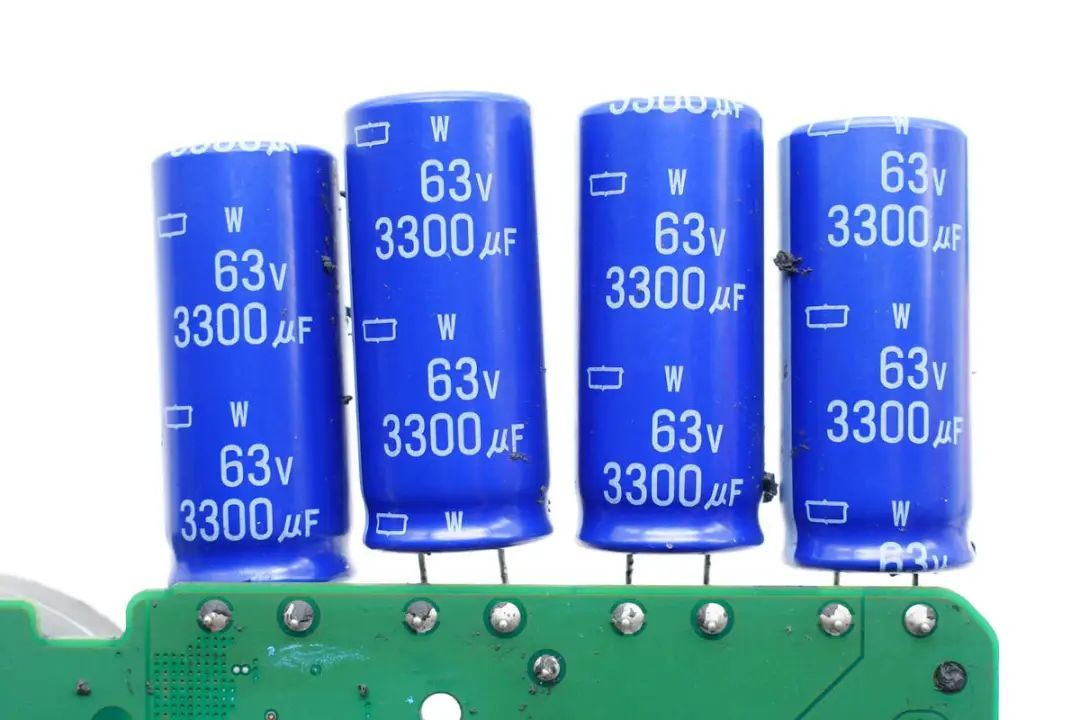

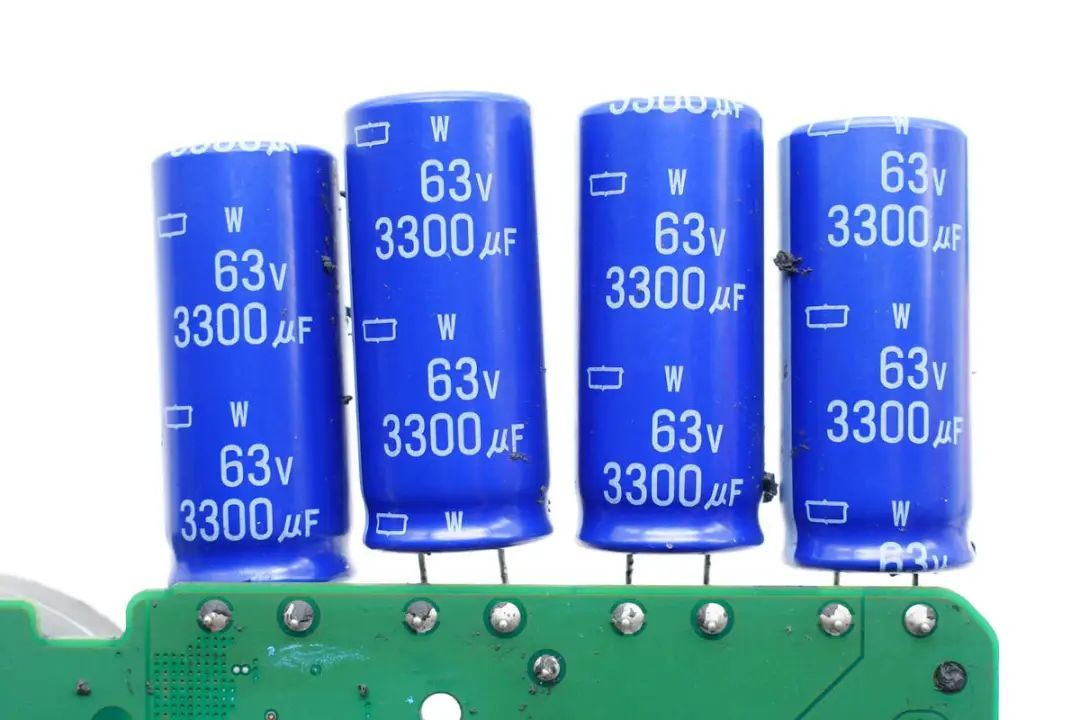

The direct current input from the solar panels passes through four electrolytic capacitors and one inductor for filtering. The four electrolytic capacitors are from KEMET, with a specification of 63V 3300μF, connected in parallel.

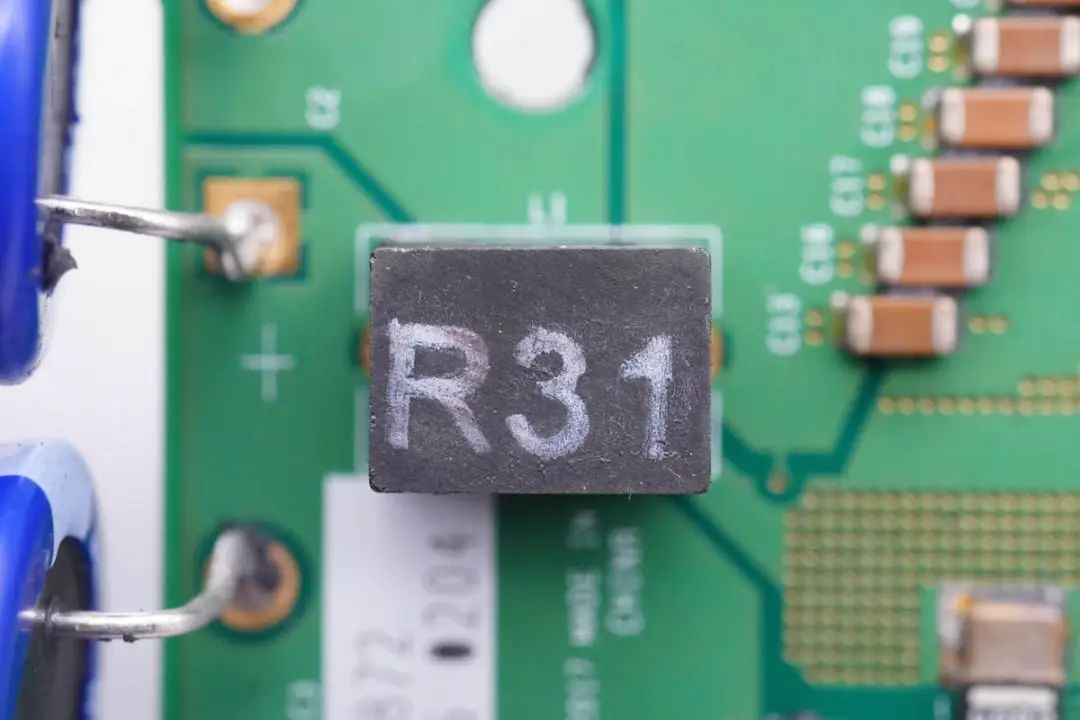

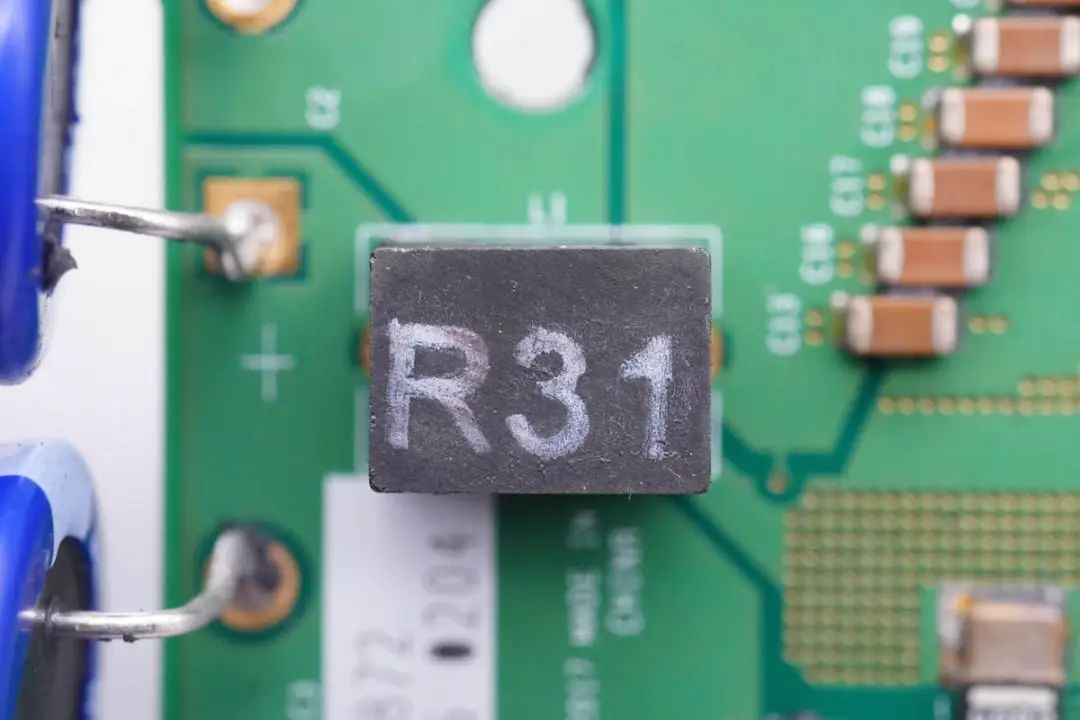

A close-up of the input filter inductor.

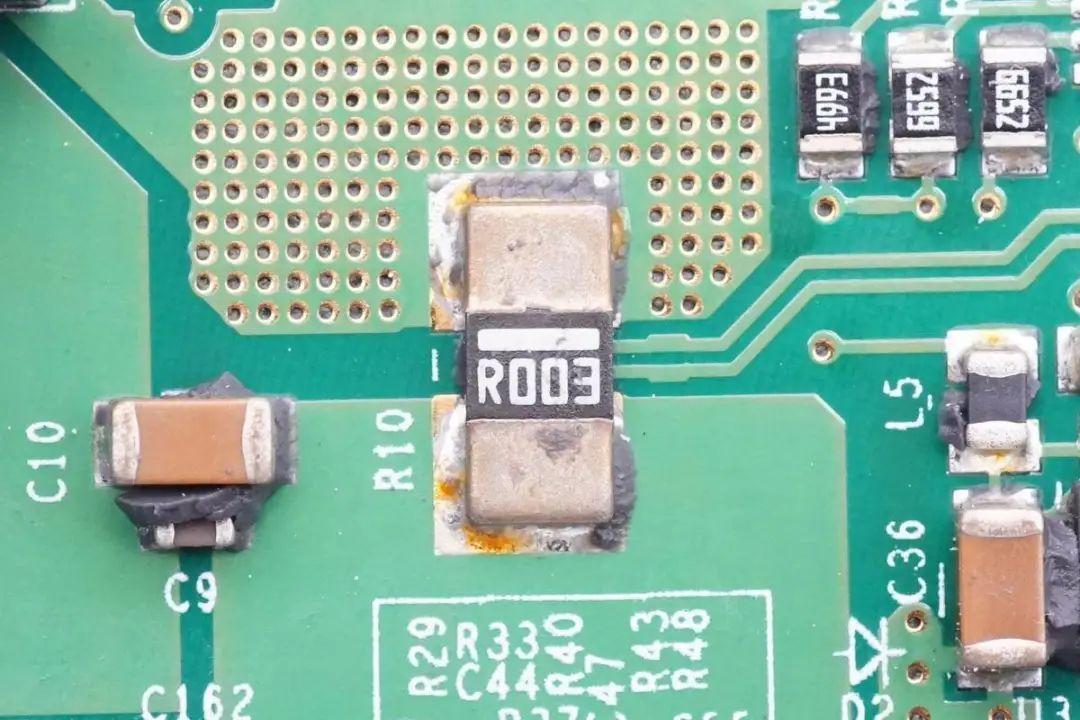

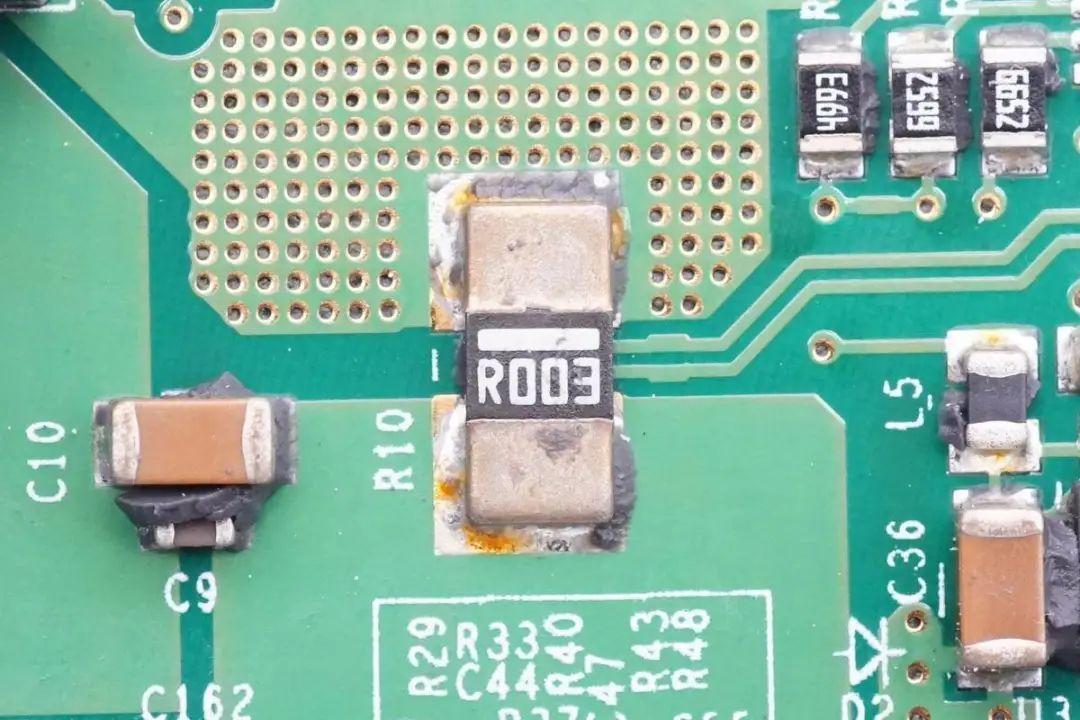

A 3mΩ resistor is used for measuring the DC input current to the inverter.

The main control chip for the inverter is from ENPHASE, with markings "480-00031-01" and "PFA048.00A-C1 2141." This chip controls the direct current boost and output modulation, with low voltage direct drive and high voltage drive using isolation drivers.

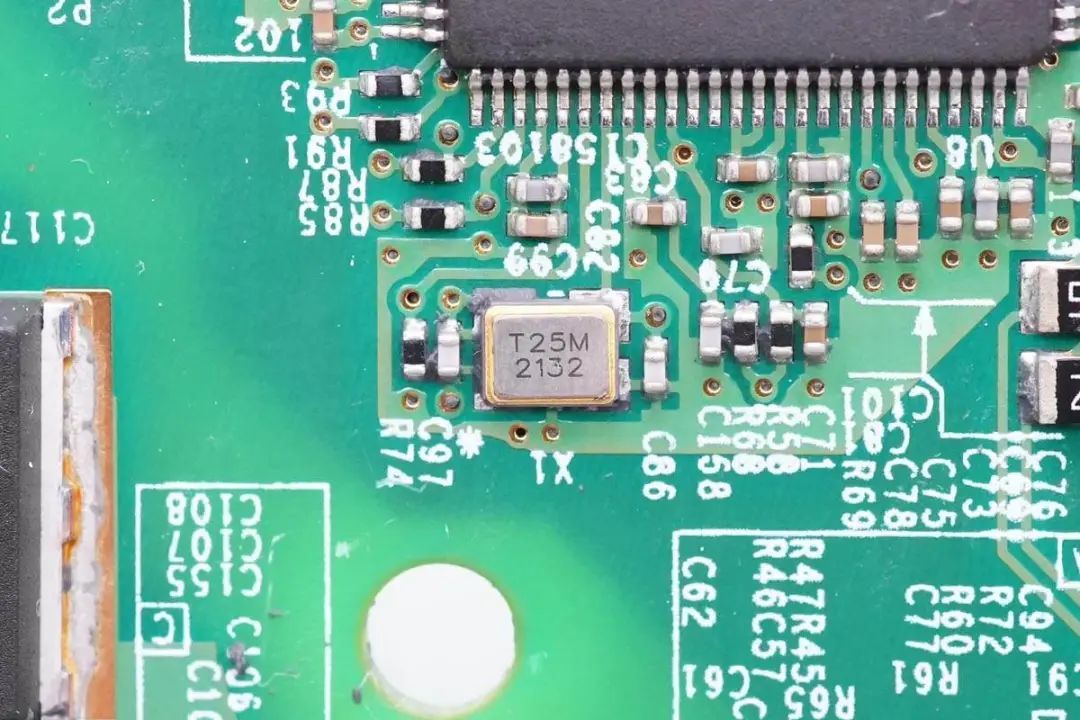

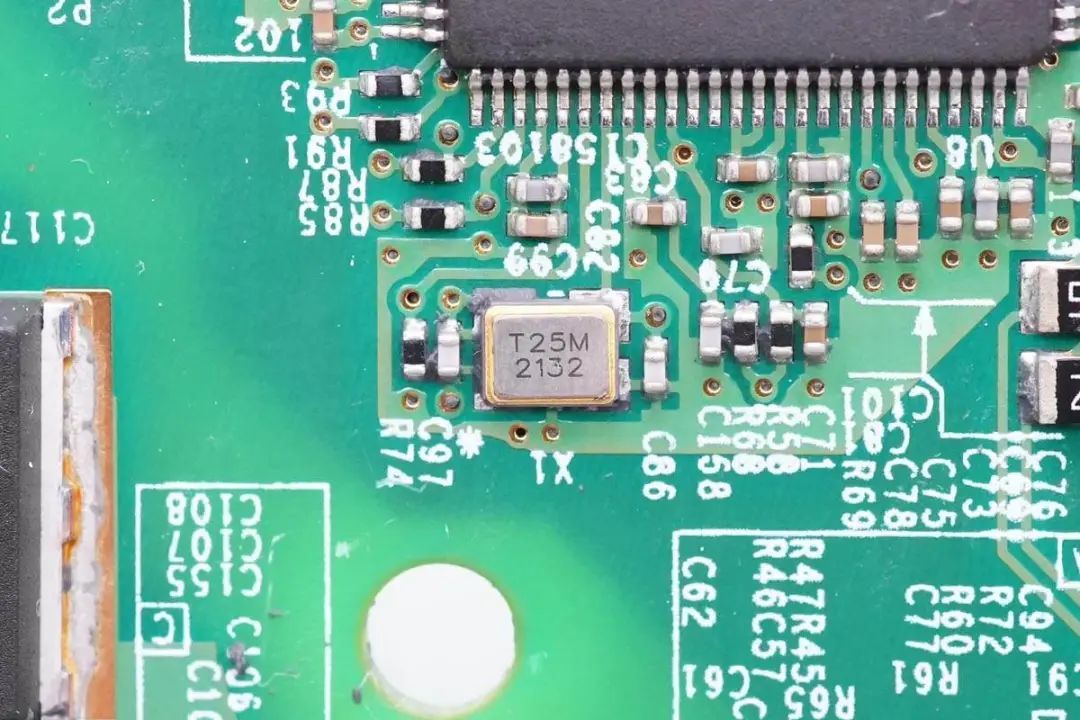

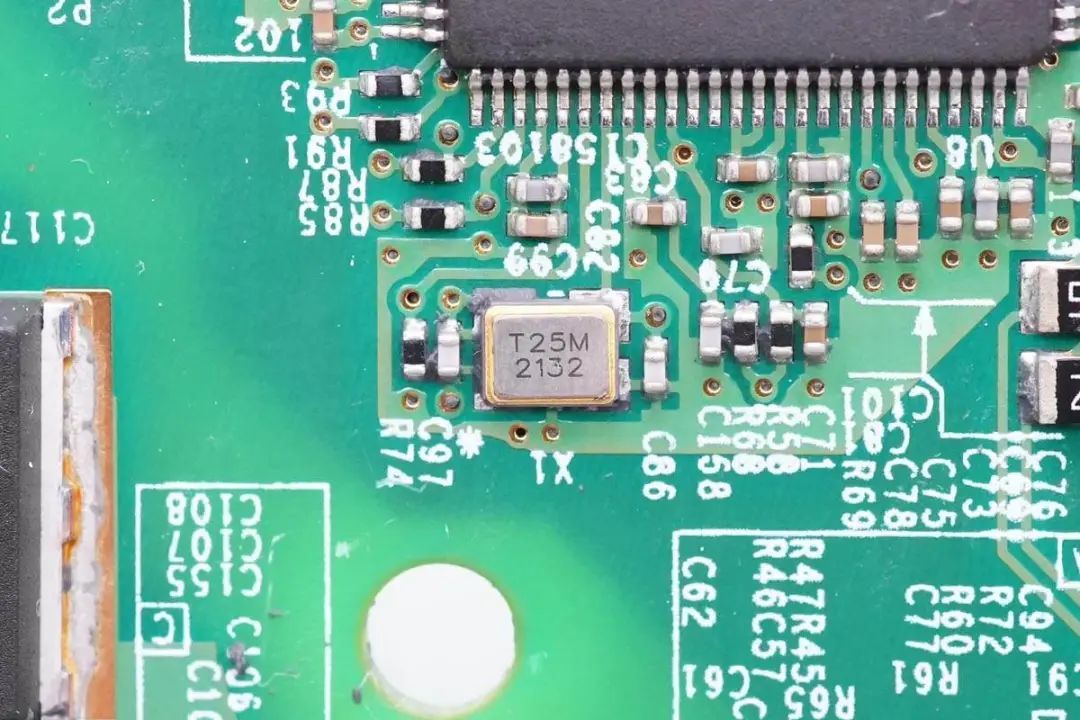

A close-up of the external clock crystal for the main control chip.

The external storage memory for the main control chip is from GigaDevice.

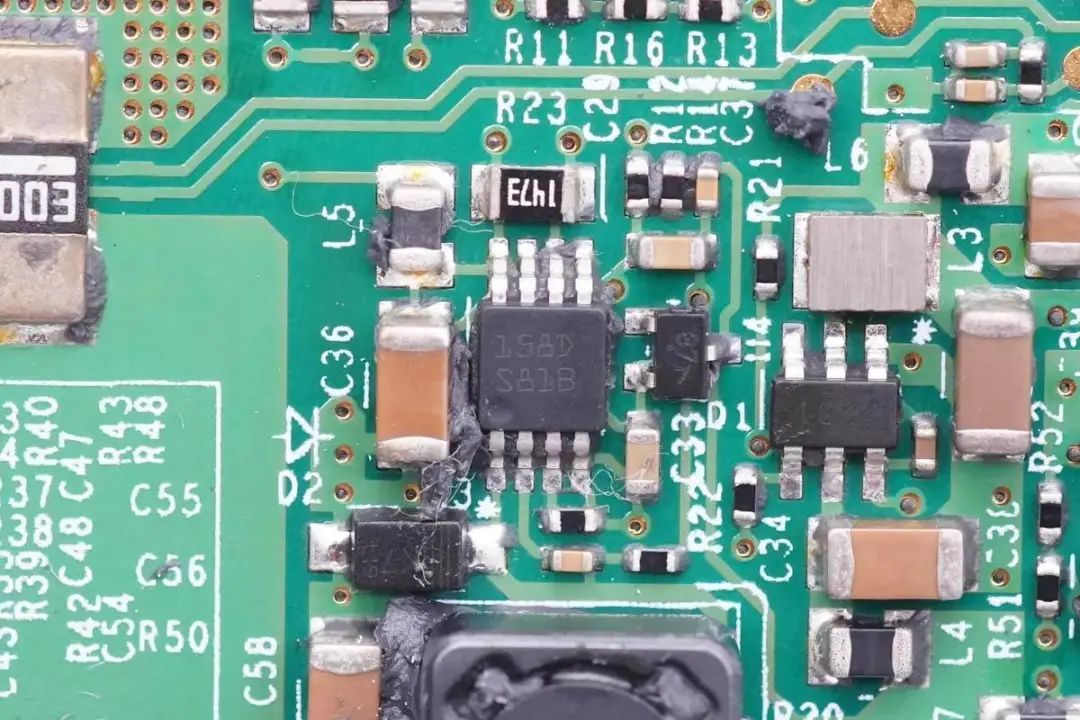

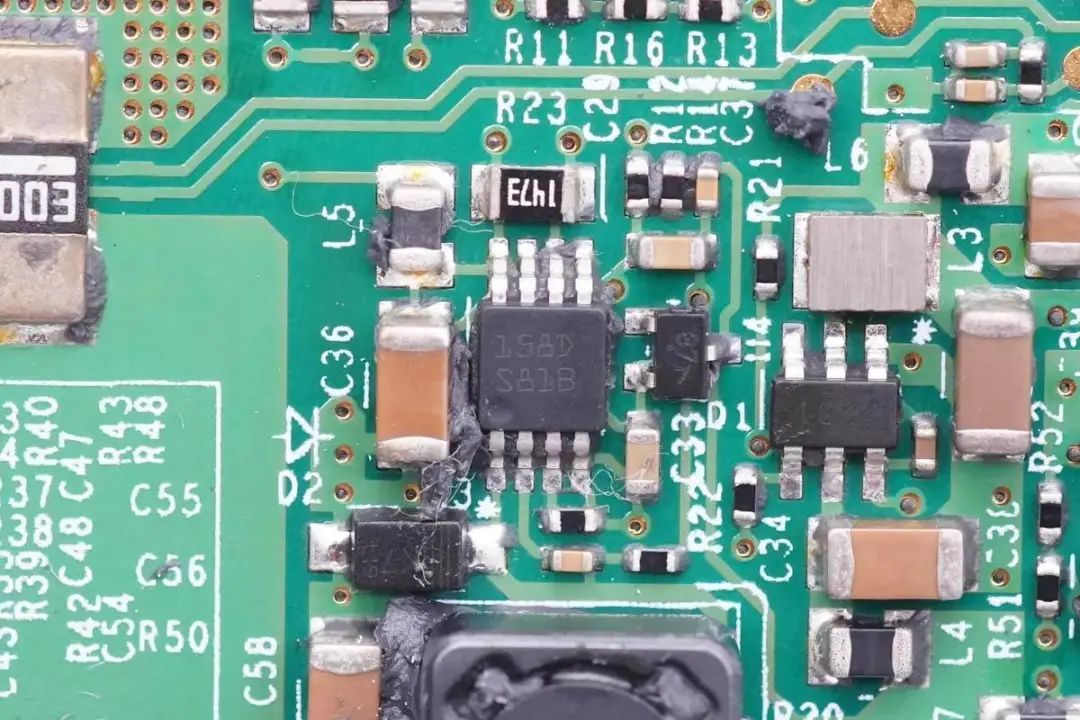

Two buck converters, providing power to the main control chip, are from Texas Instruments.

with one marked "158D."

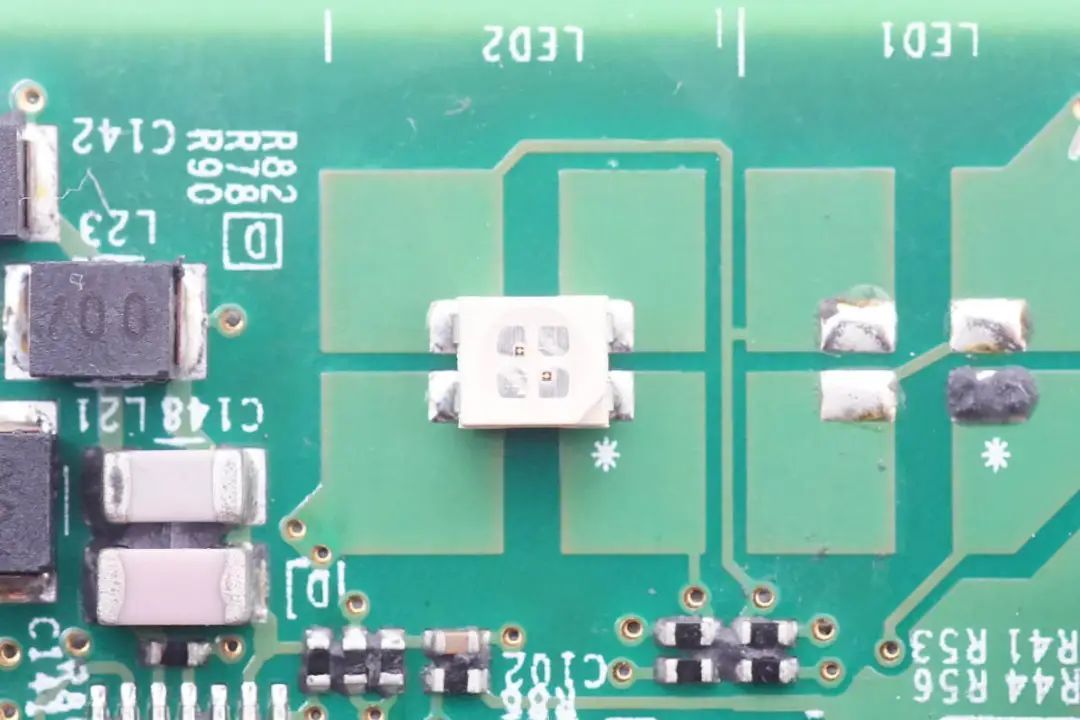

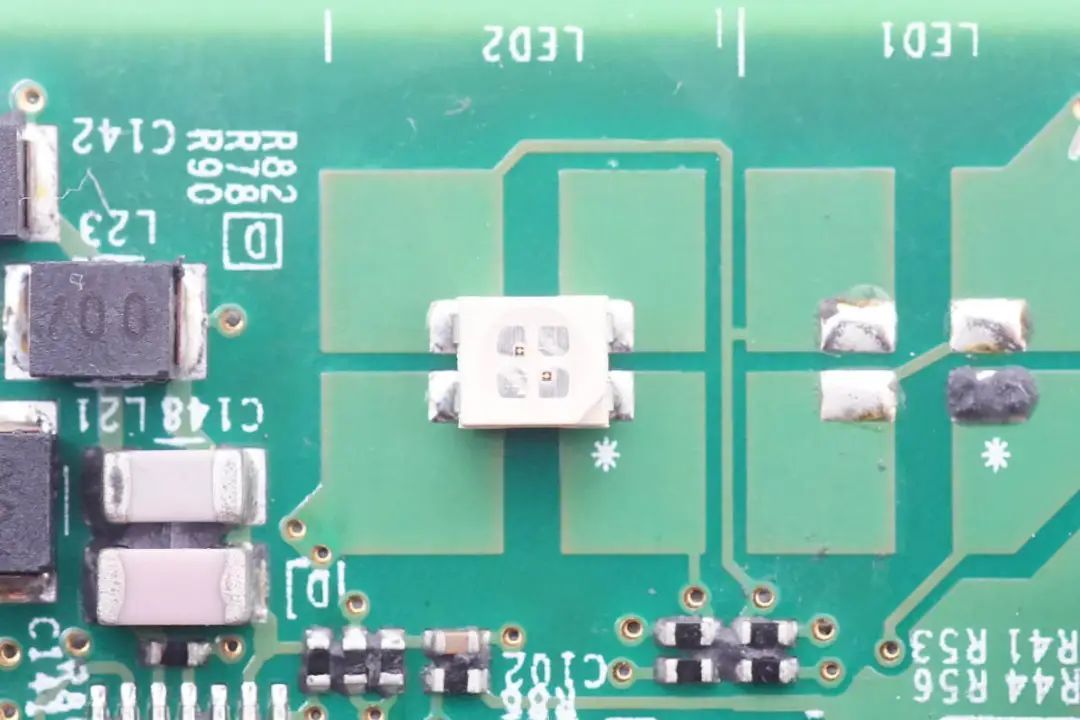

A close-up of the status indicator.

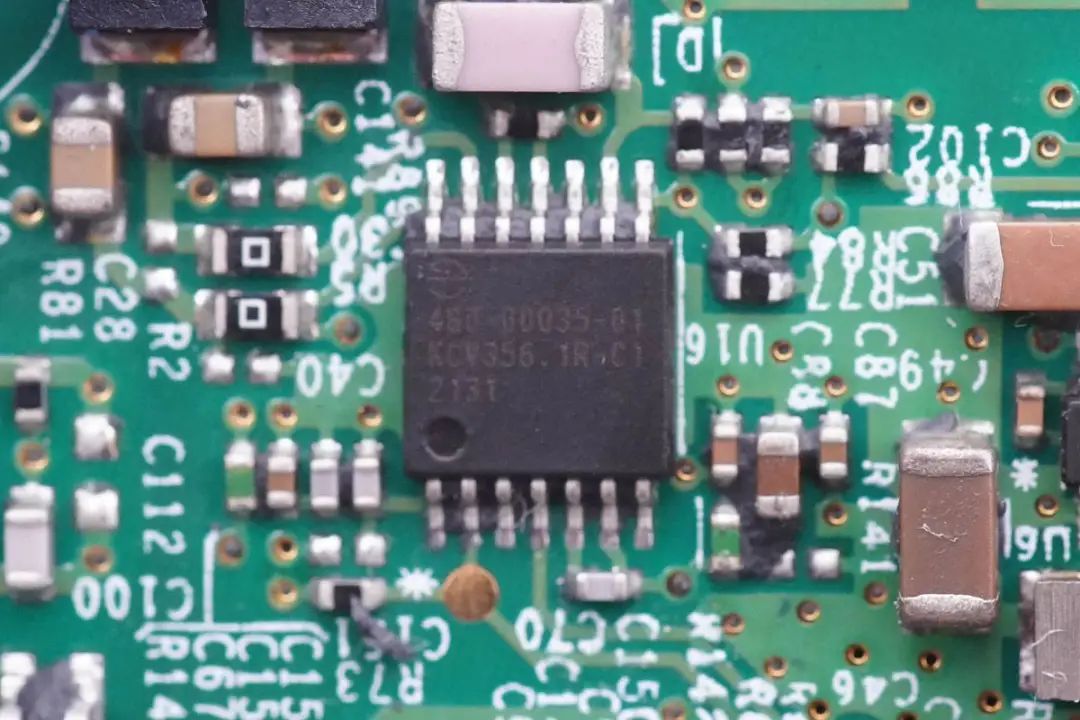

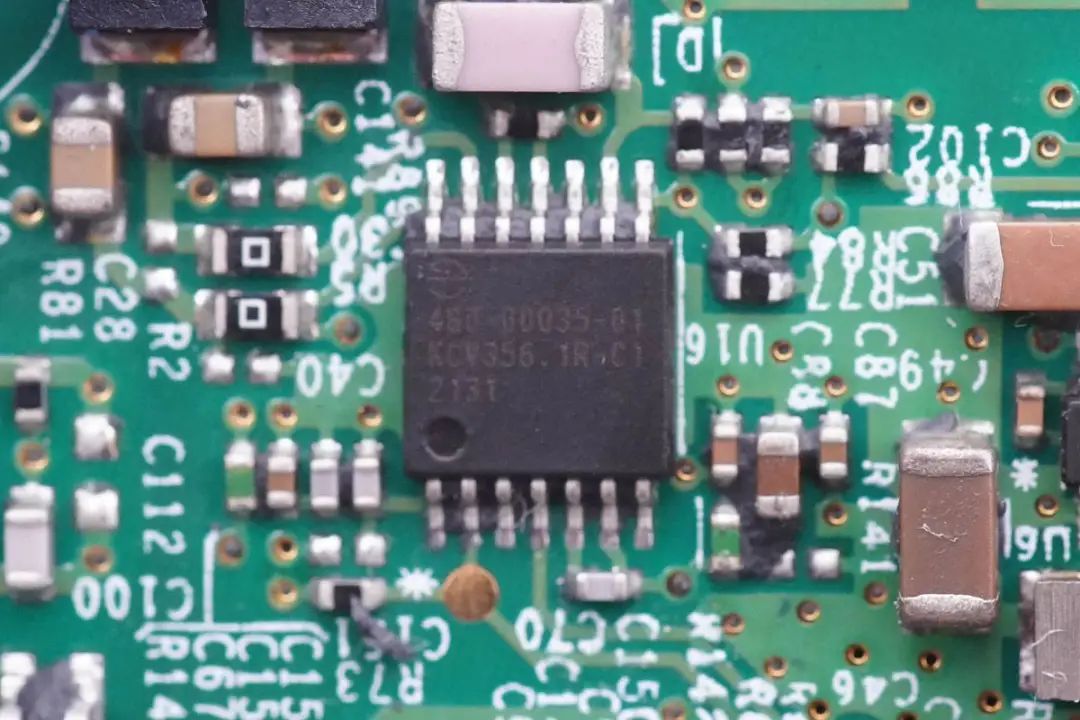

Another custom chip by ENPHASE.

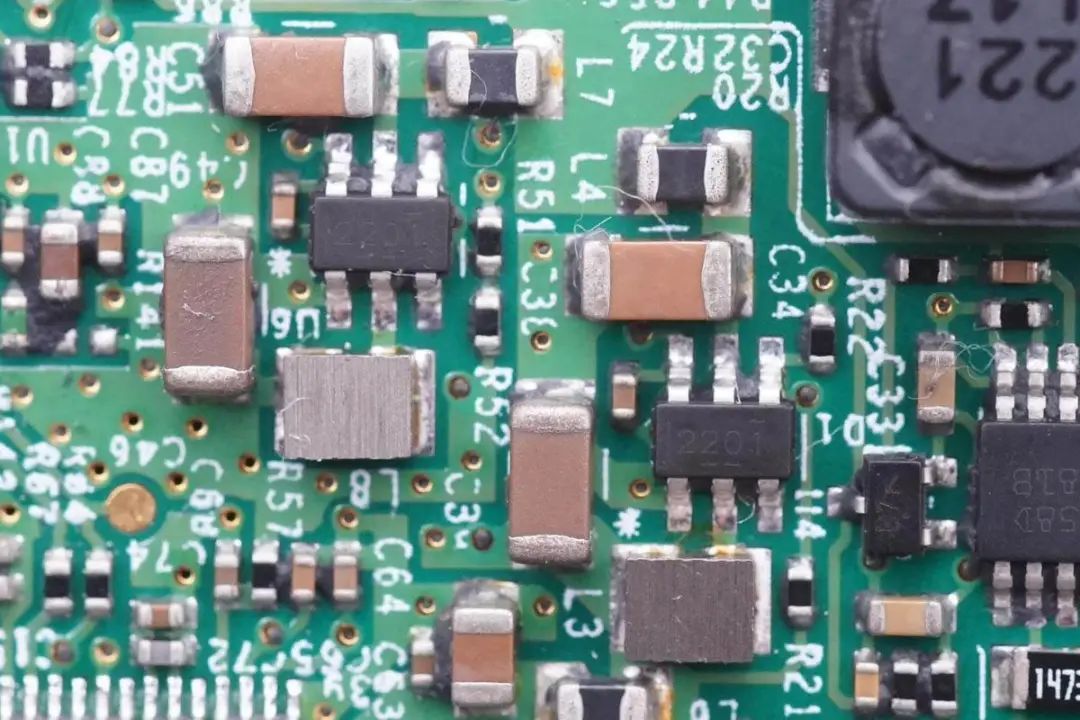

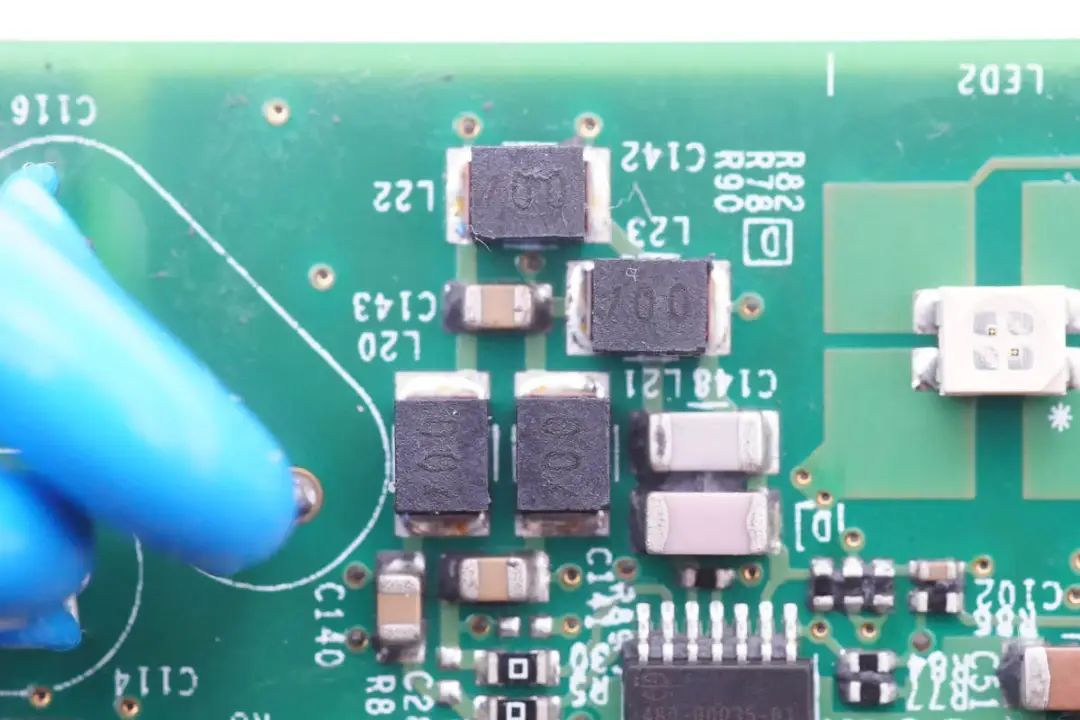

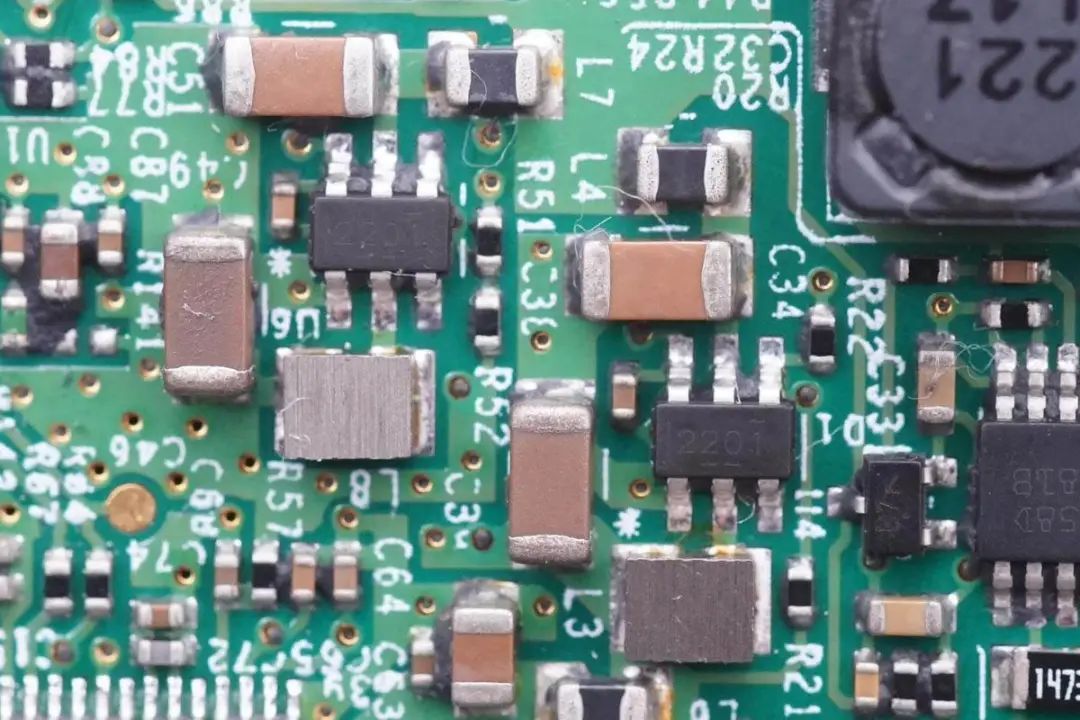

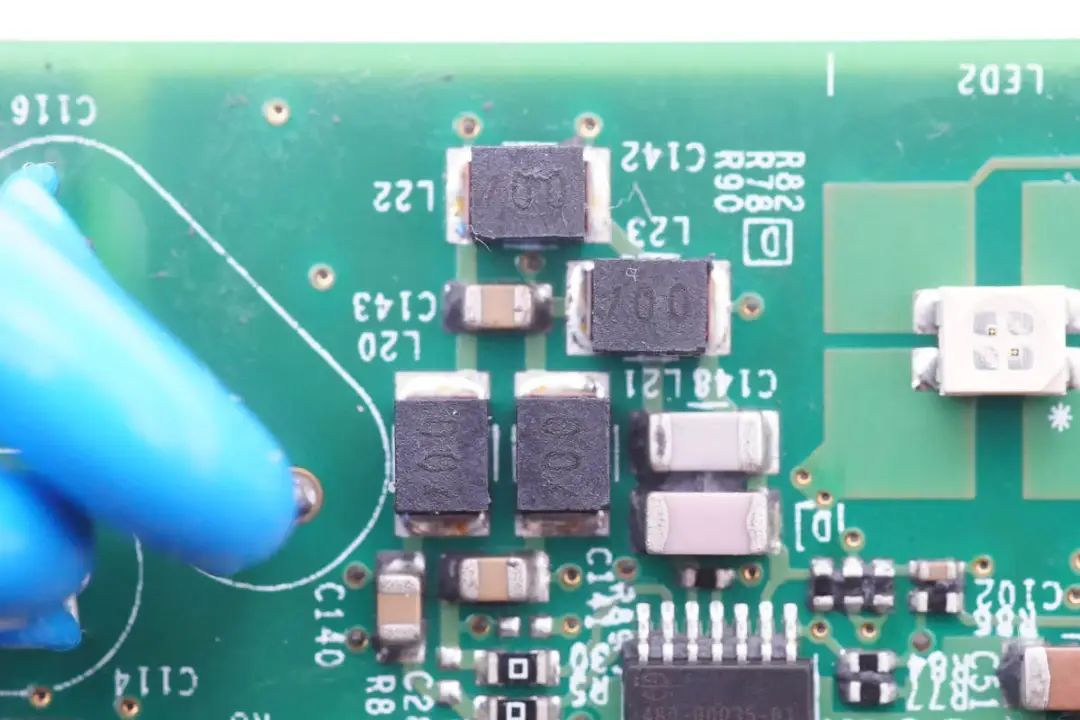

A close-up of the inductors and capacitors around the chips.

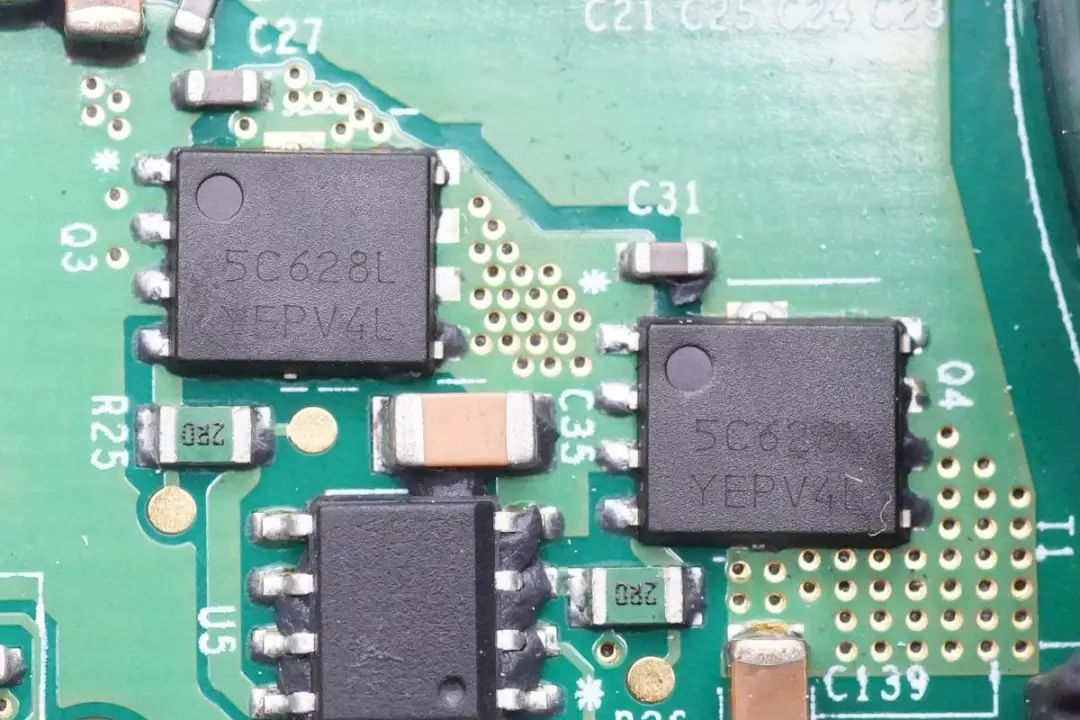

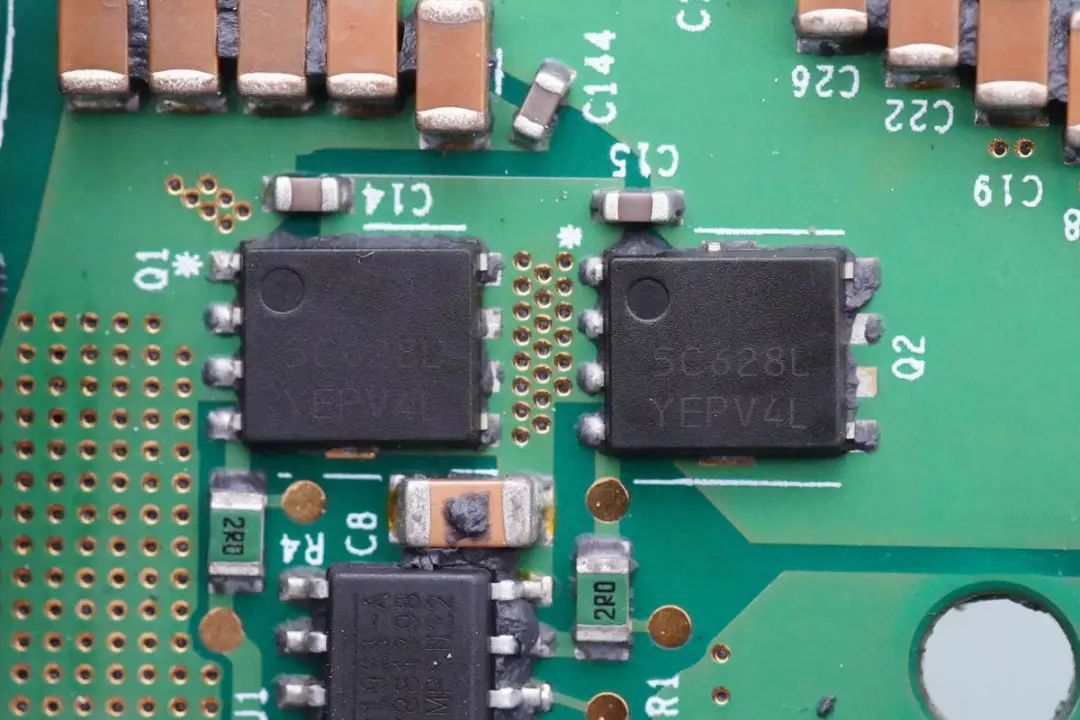

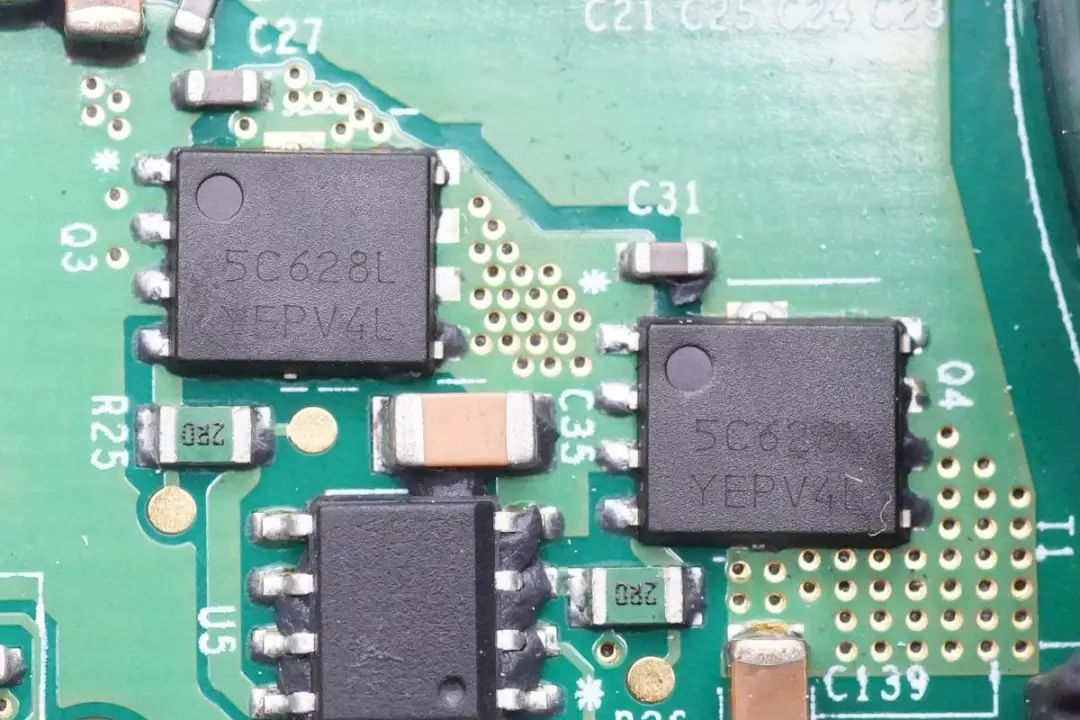

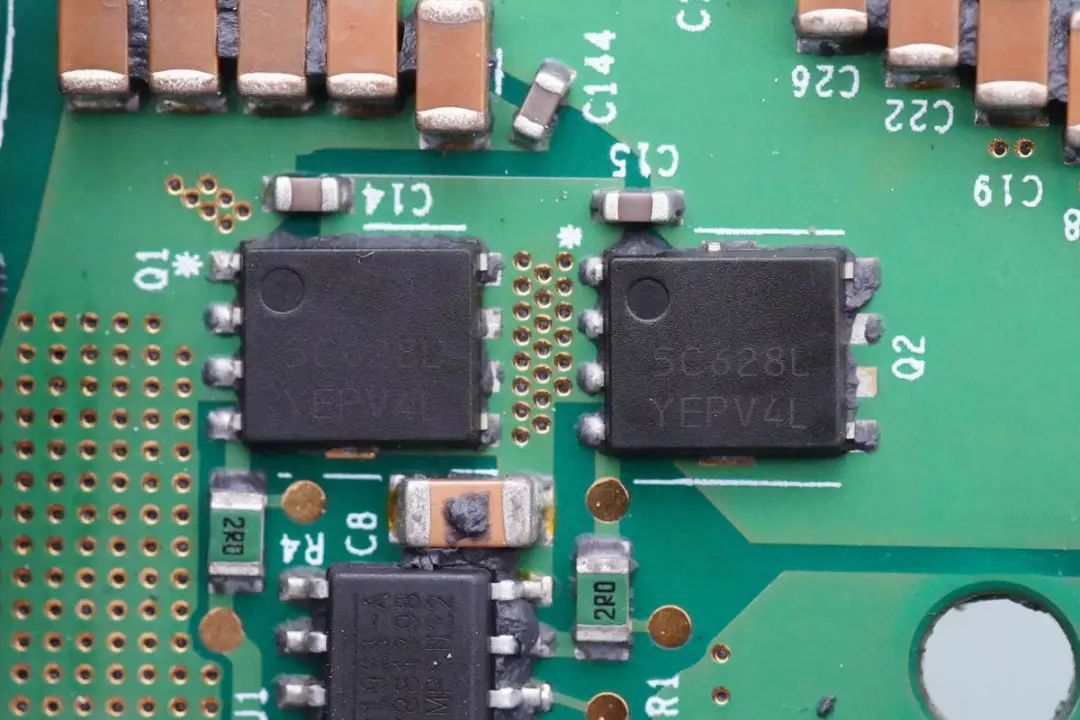

For the direct current input, four ON Semiconductor NTMFS5C628NL MOSFETs are used to form an H-bridge. These are NMOS transistors with a 60V rating and 2.4mΩ on-resistance.

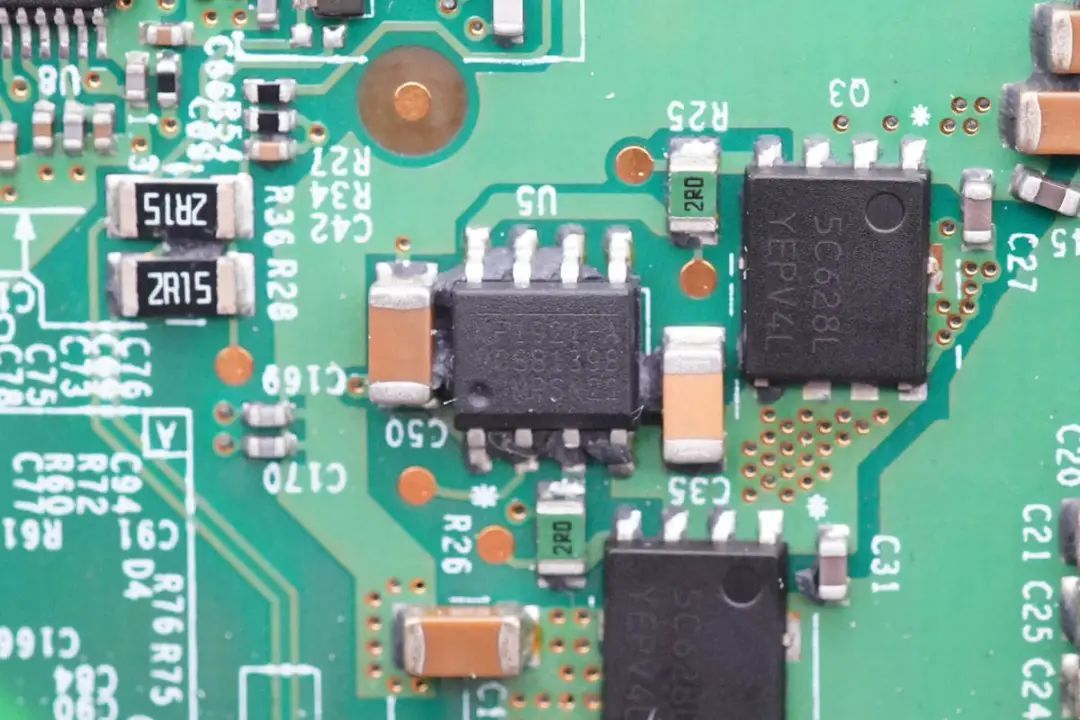

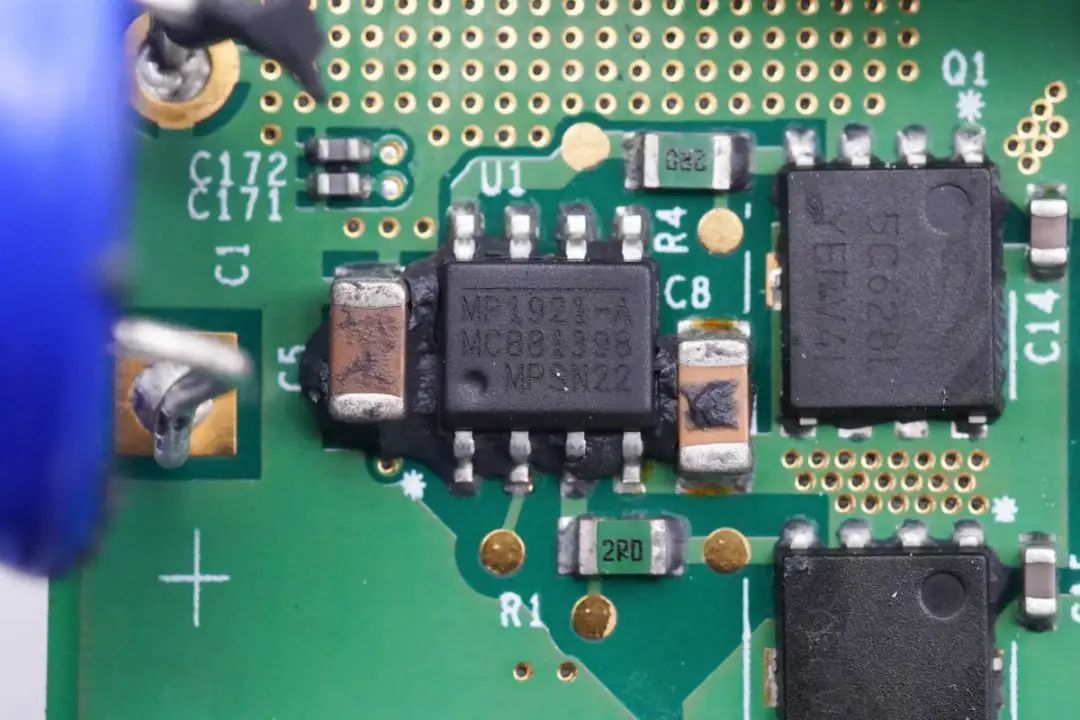

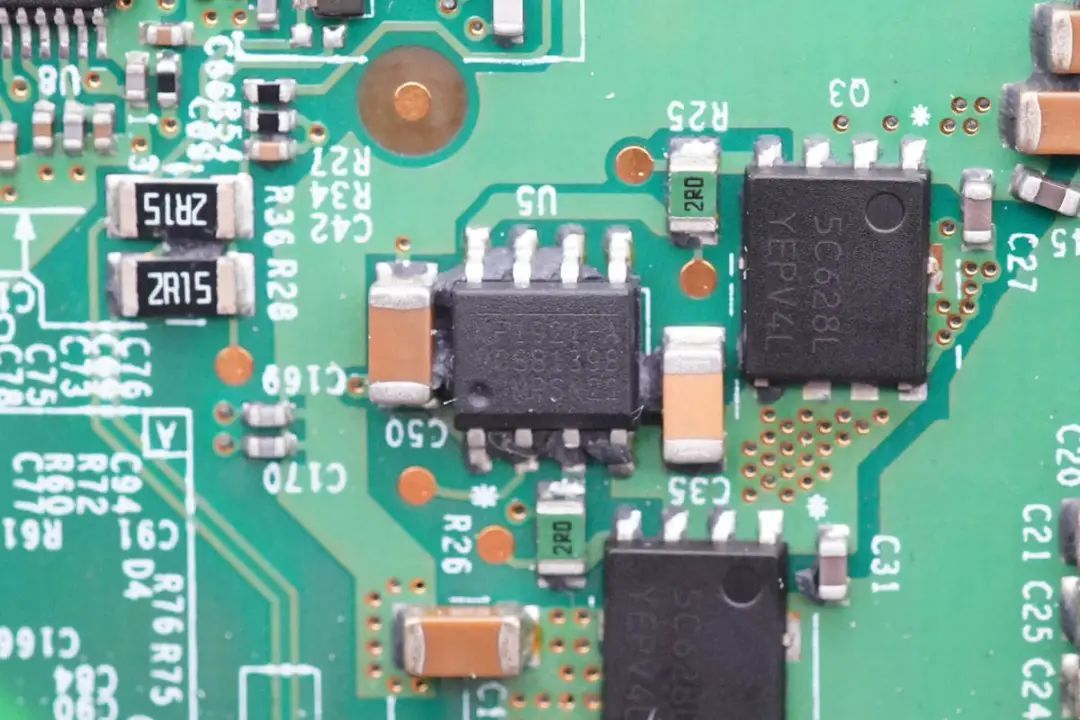

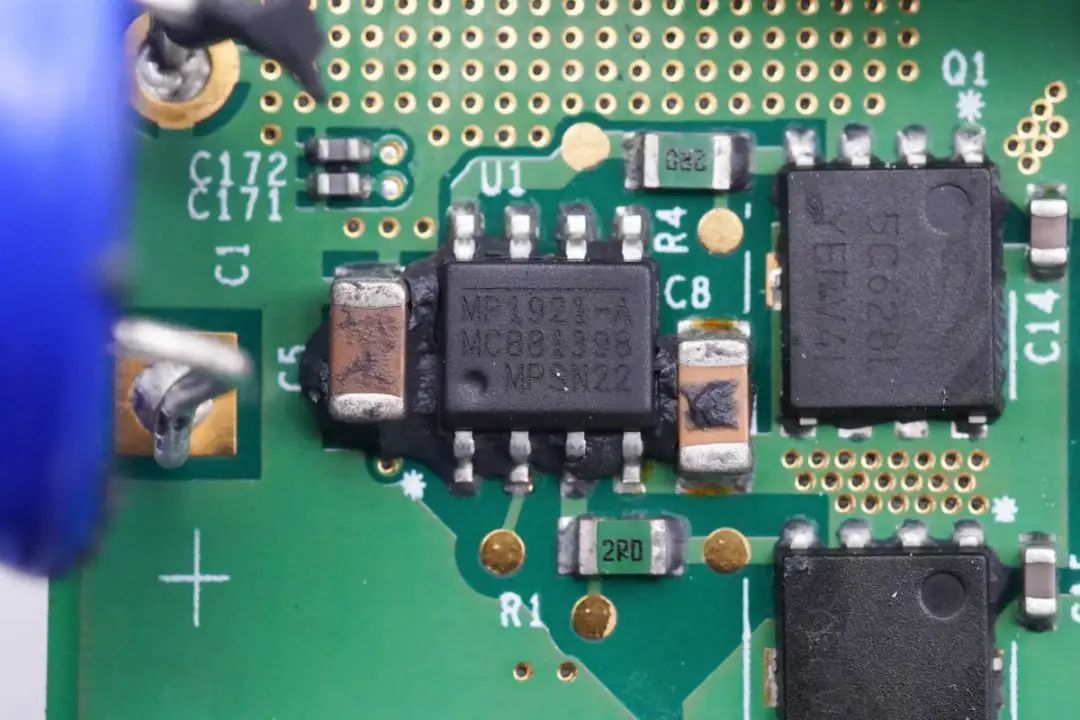

The drivers for low-voltage MOSFETs are from MPS, specifically the MP1921A, a 100V half-bridge driver with an integrated bootstrap diode, allowing independent control of the upper and lower transistors.

Two NTMFS5C628NL MOSFETs for the other half of the bridge.

MPS half-bridge driver for the other half of the bridge.

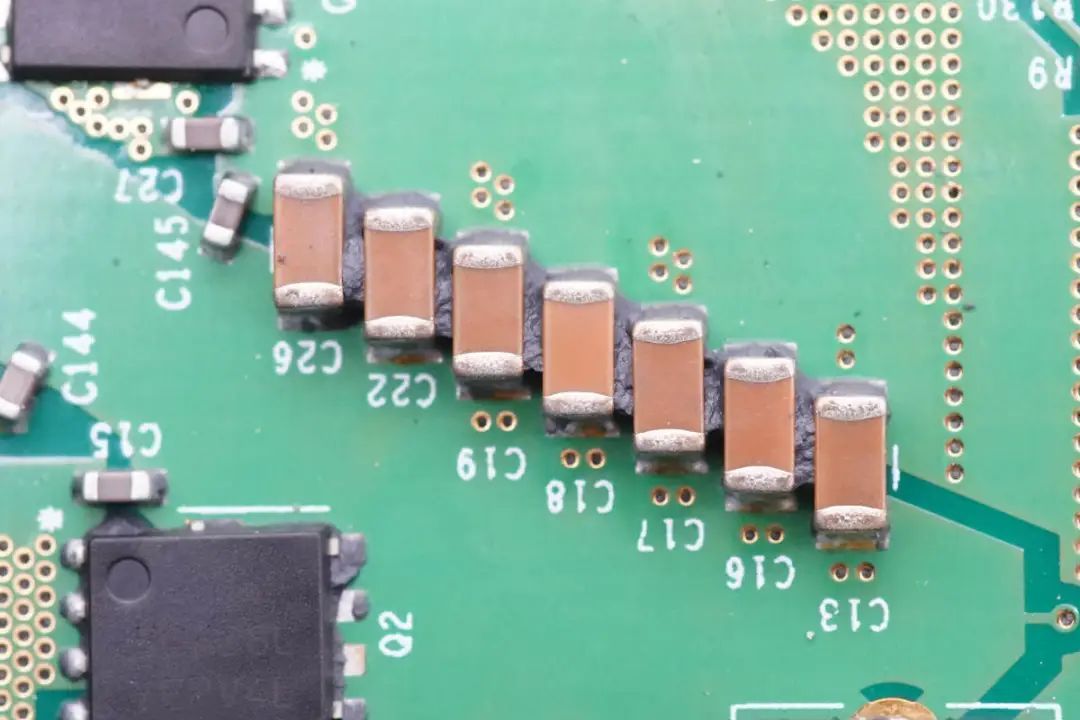

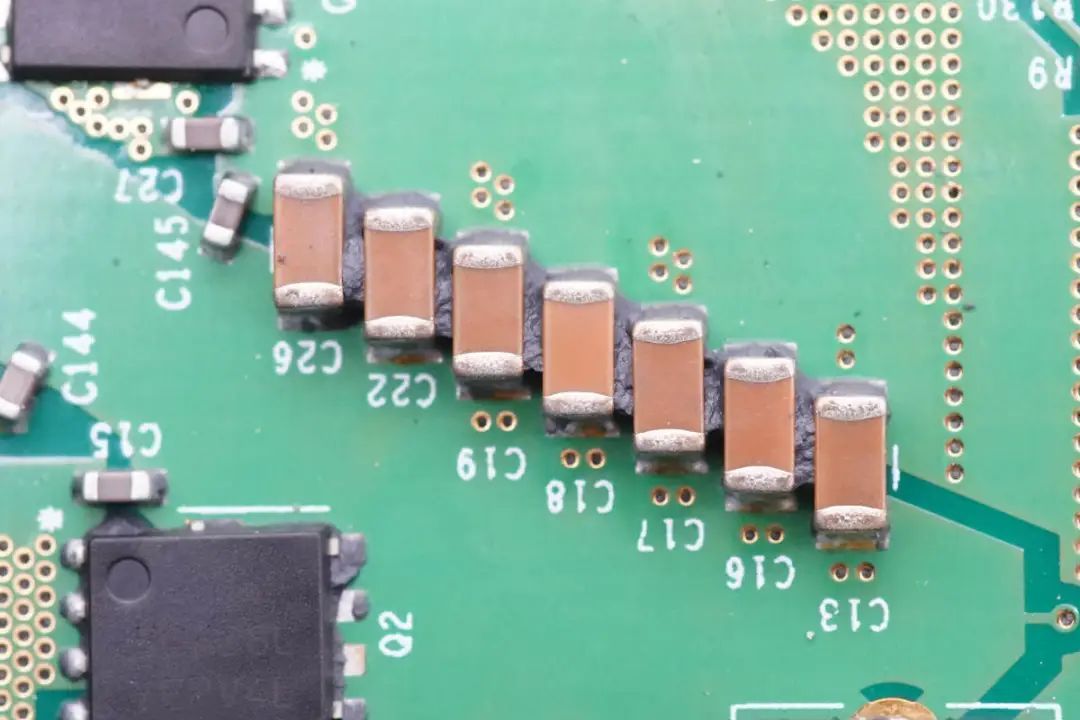

Multilayer ceramic capacitors (MLCCs) for direct current input filtering.

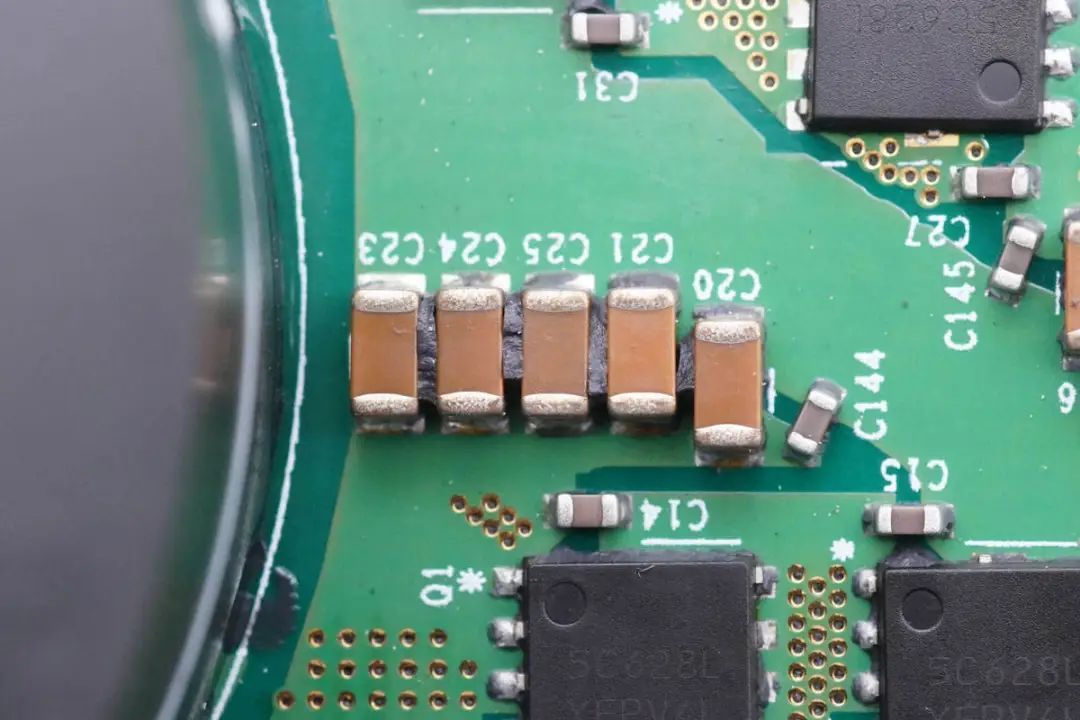

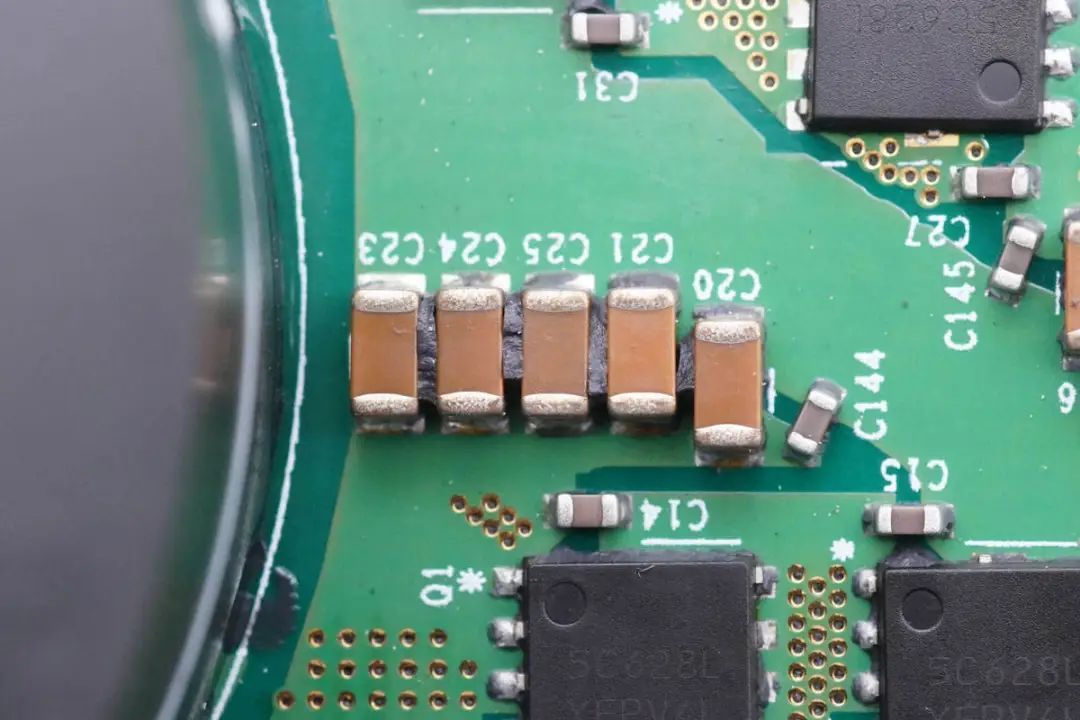

Another set of MLCCs for filtering.

The inverter transformer is from EPCOS, featuring a circular magnetic core with an integrated secondary current sensor.

Four output modulation MOSFETs are from Infineon, marked "60R102G7," with the actual model being "IPT60R102G7." These have a 650V rating and 102mΩ on-resistance, in a TOLL package.

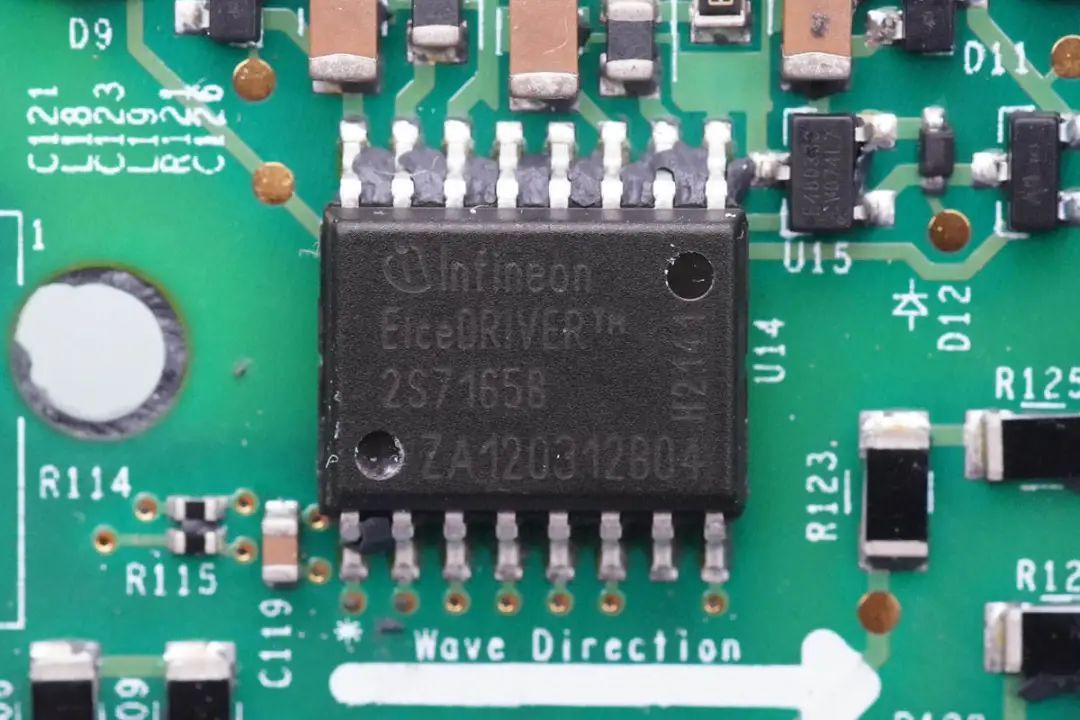

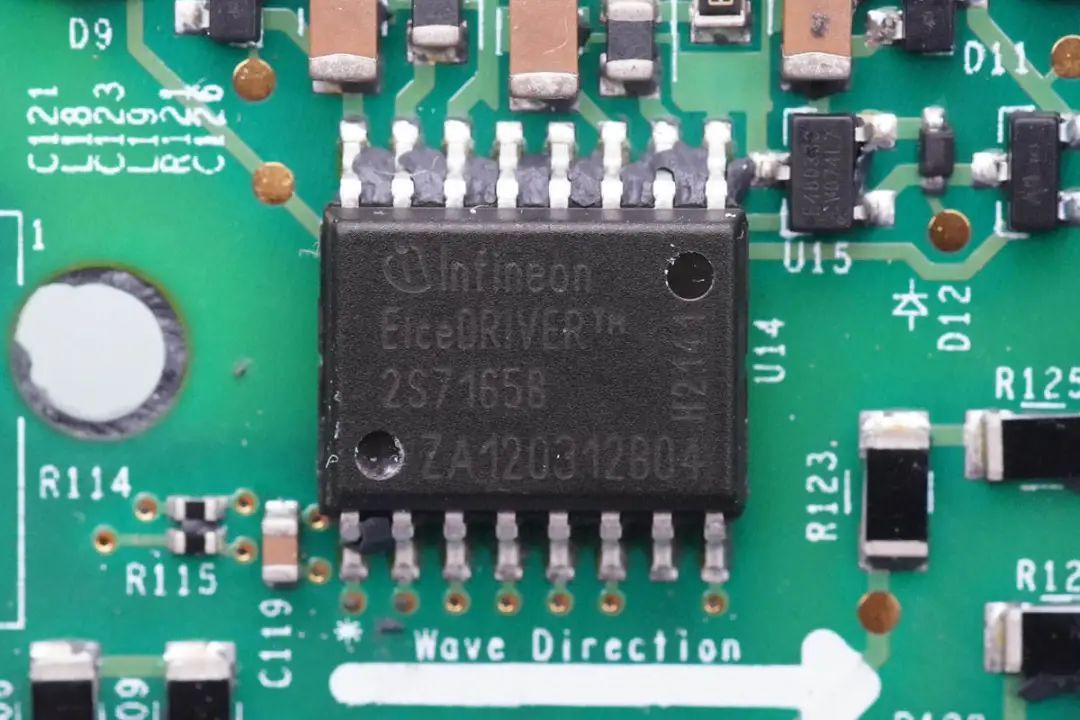

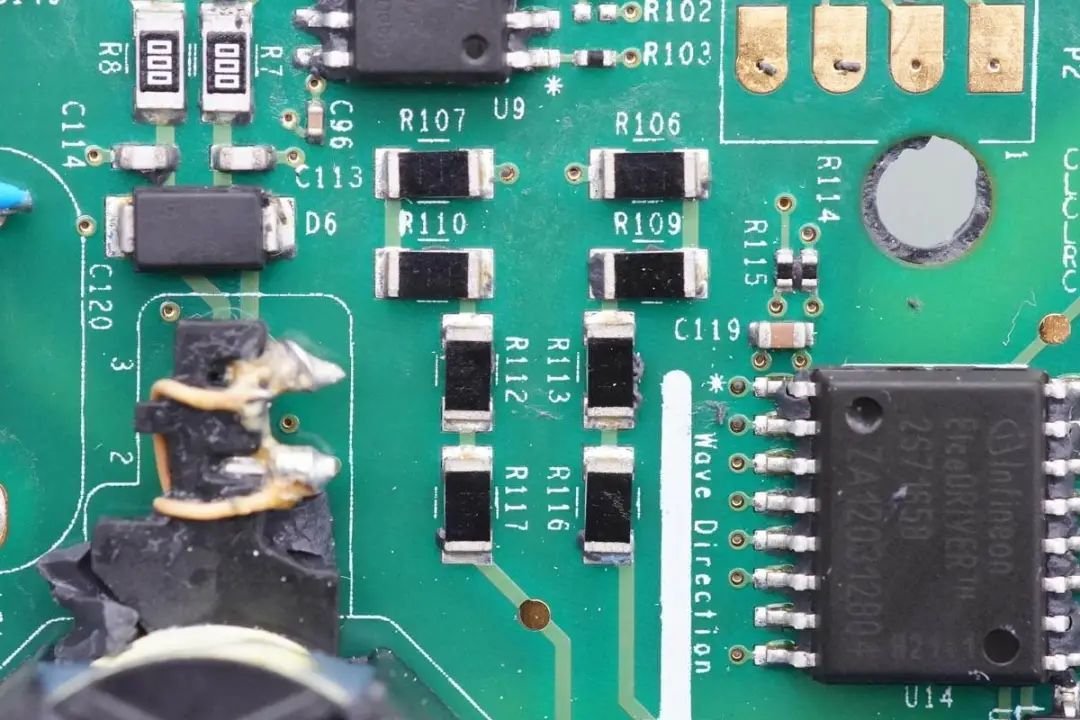

Two isolation drivers are from Infineon, marked "2S7165B," with the actual model being "2EDS7165H." These are dual-channel isolation drivers used to drive the modulation MOSFETs.

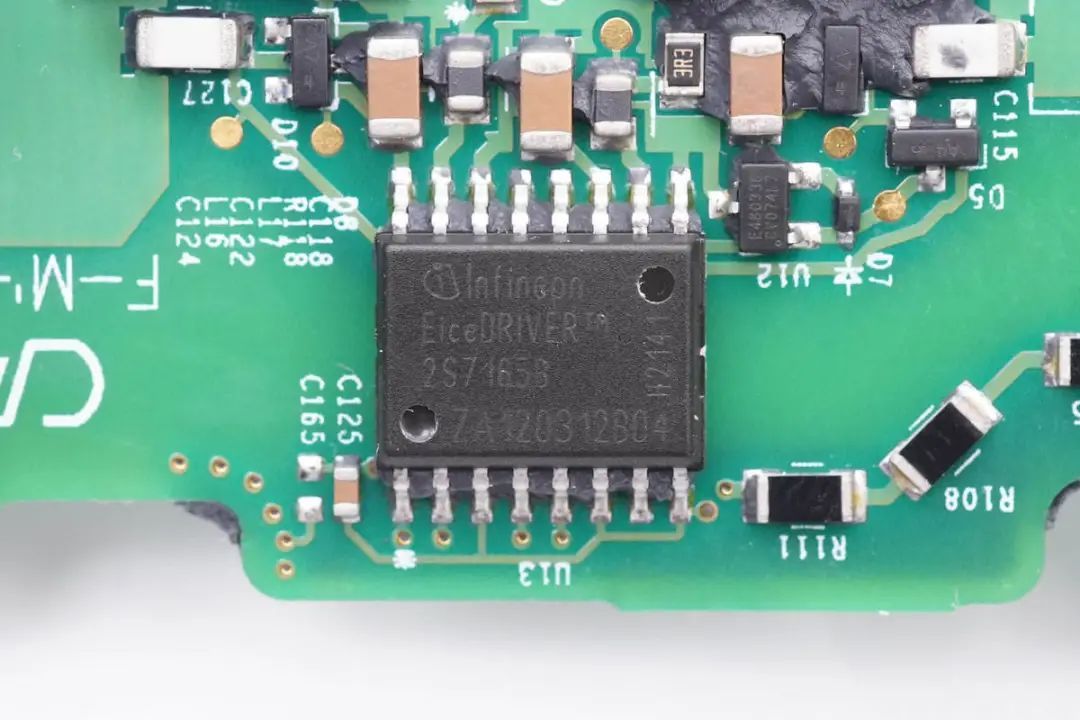

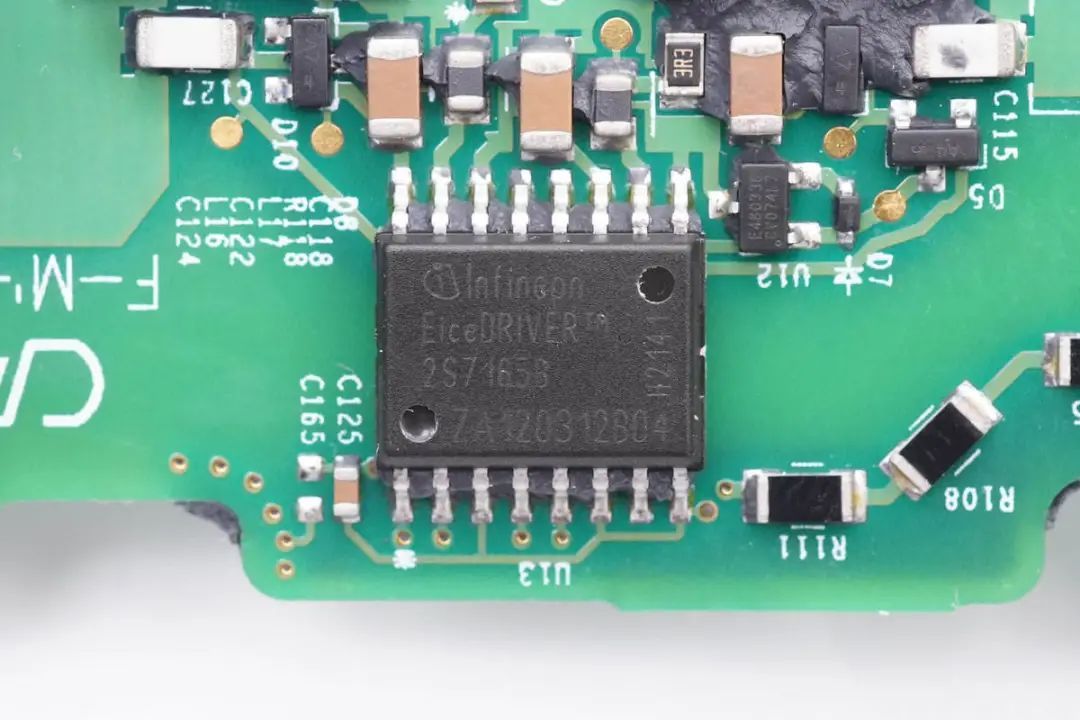

A close-up of another 2EDS7165H driver.

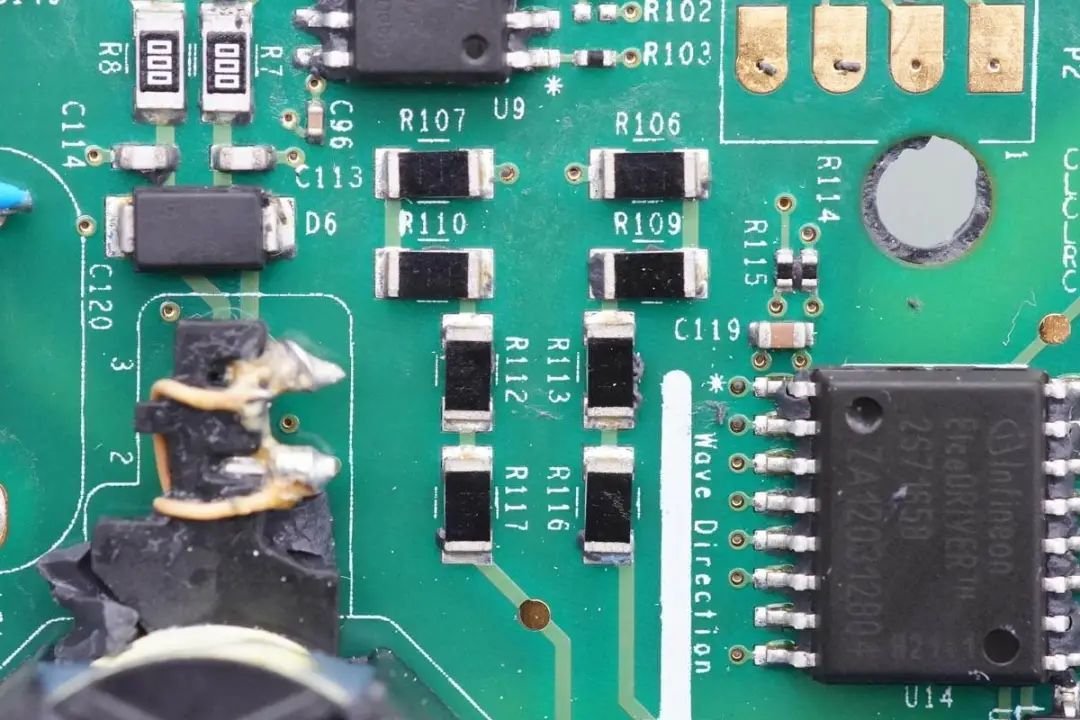

Multiple series resistors are used for voltage sensing.

A close-up of the output current sensor, used for output current detection.

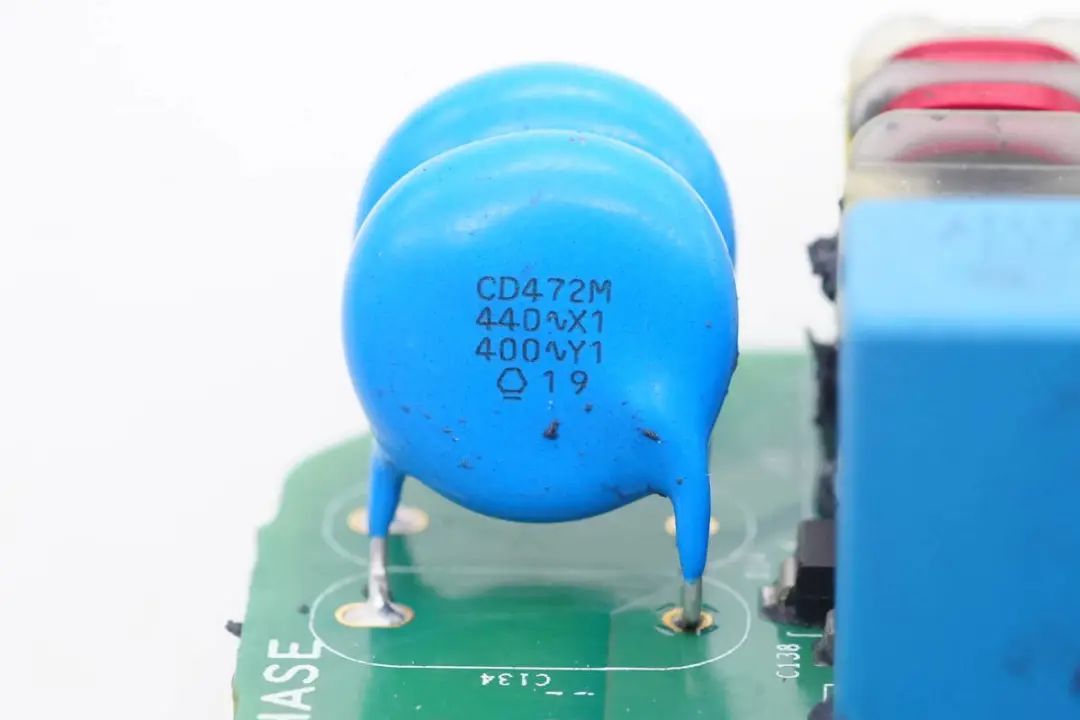

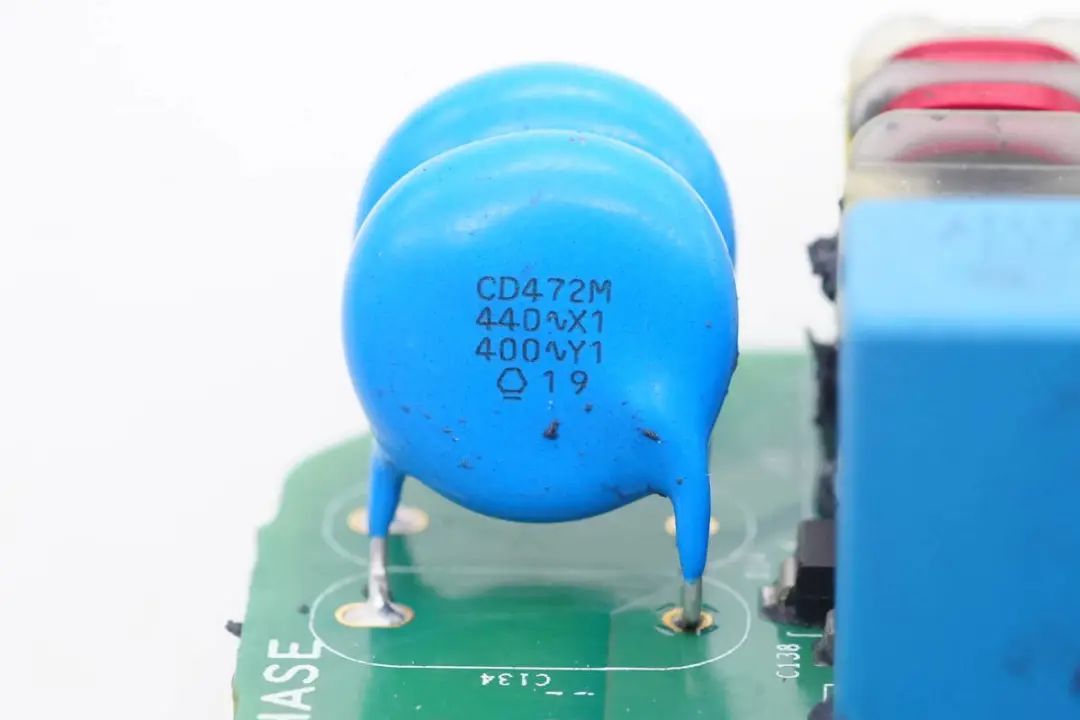

A blue Y capacitor for interference suppression.

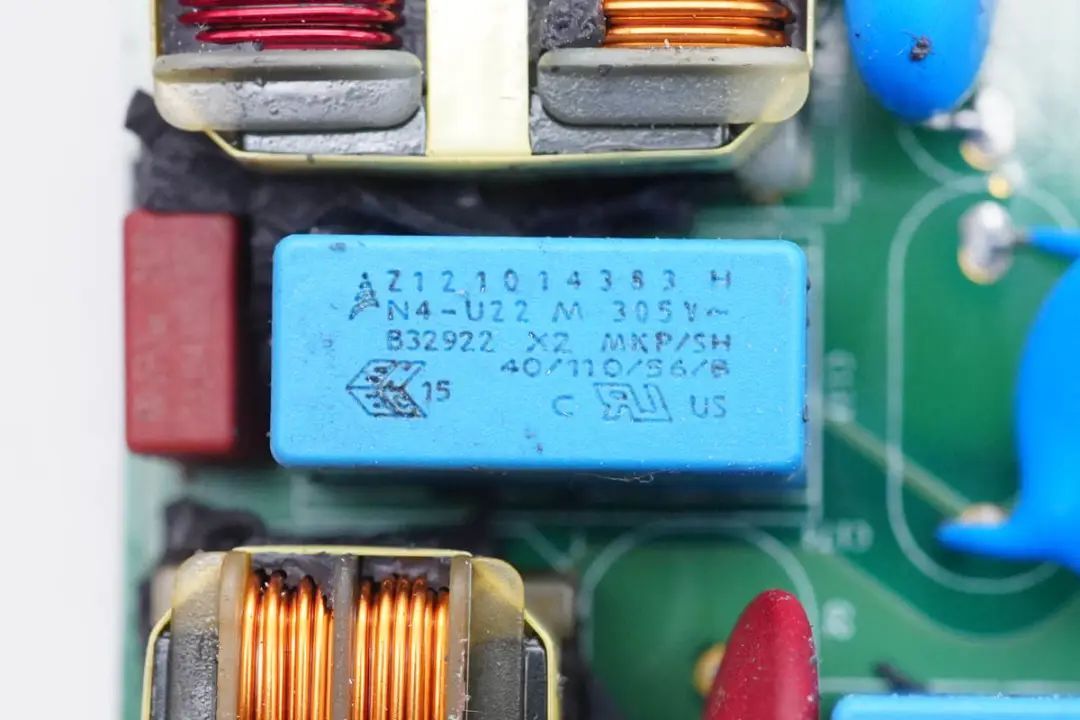

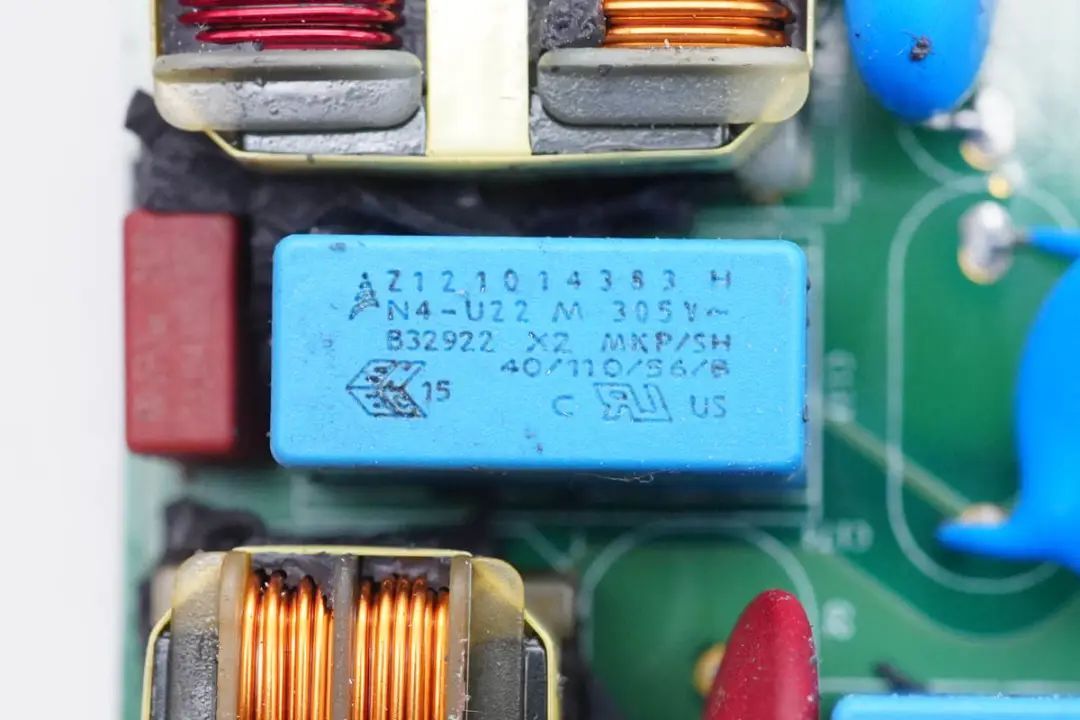

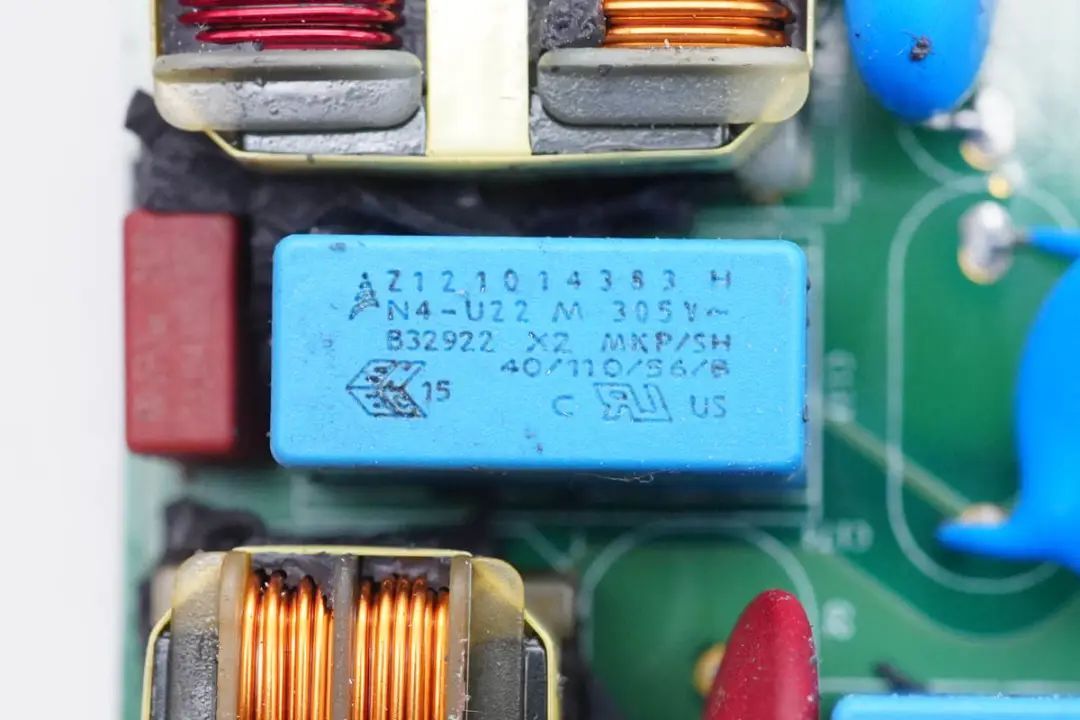

An X2 capacitor for output filtering. A Littelfuse varistor with markings "P175P10C."

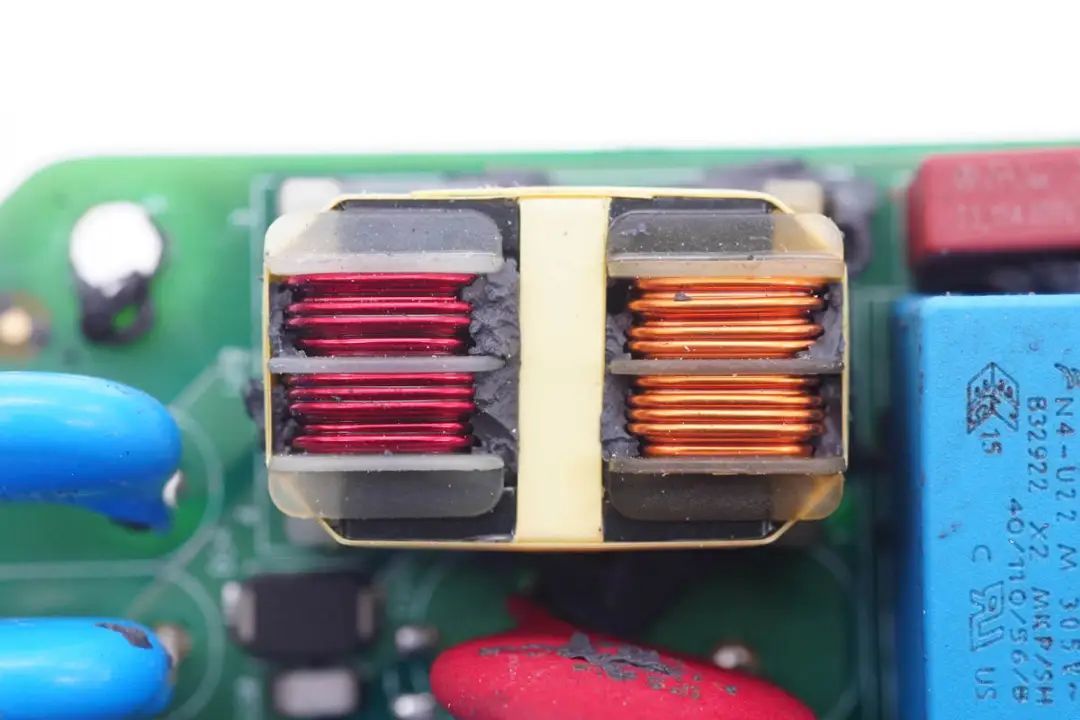

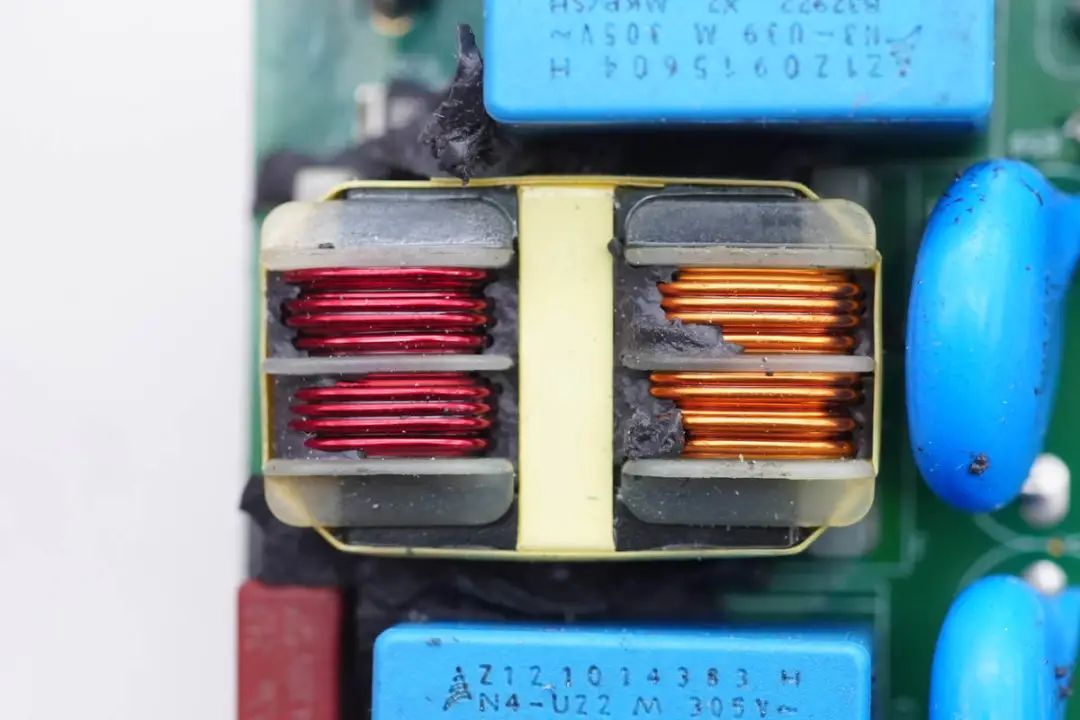

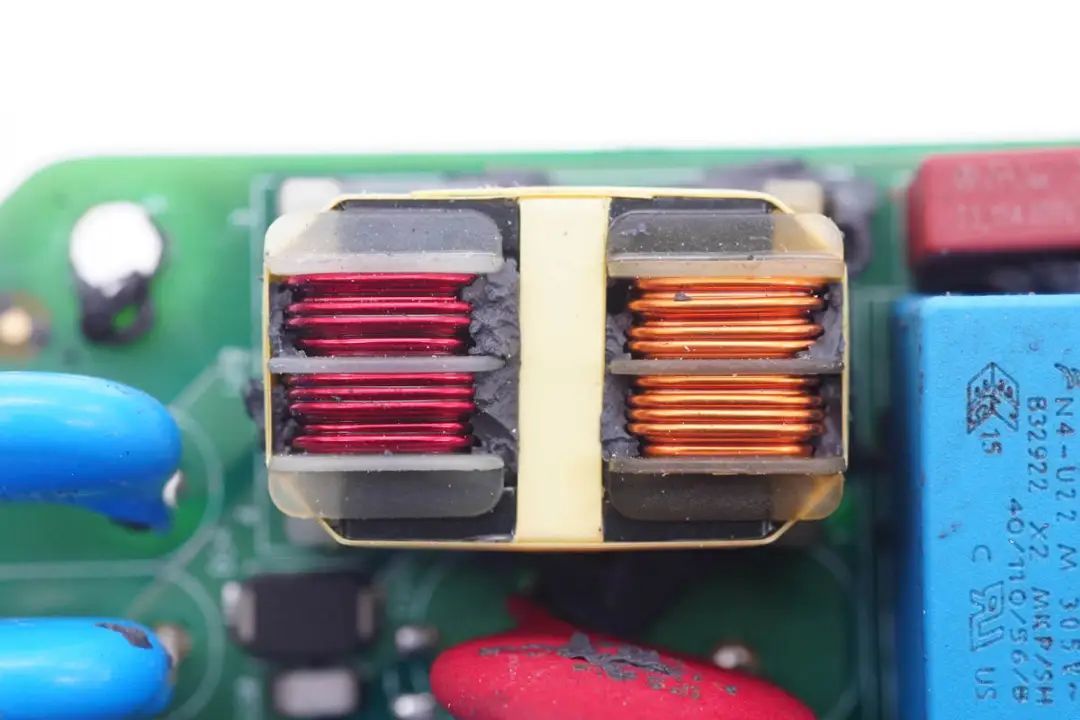

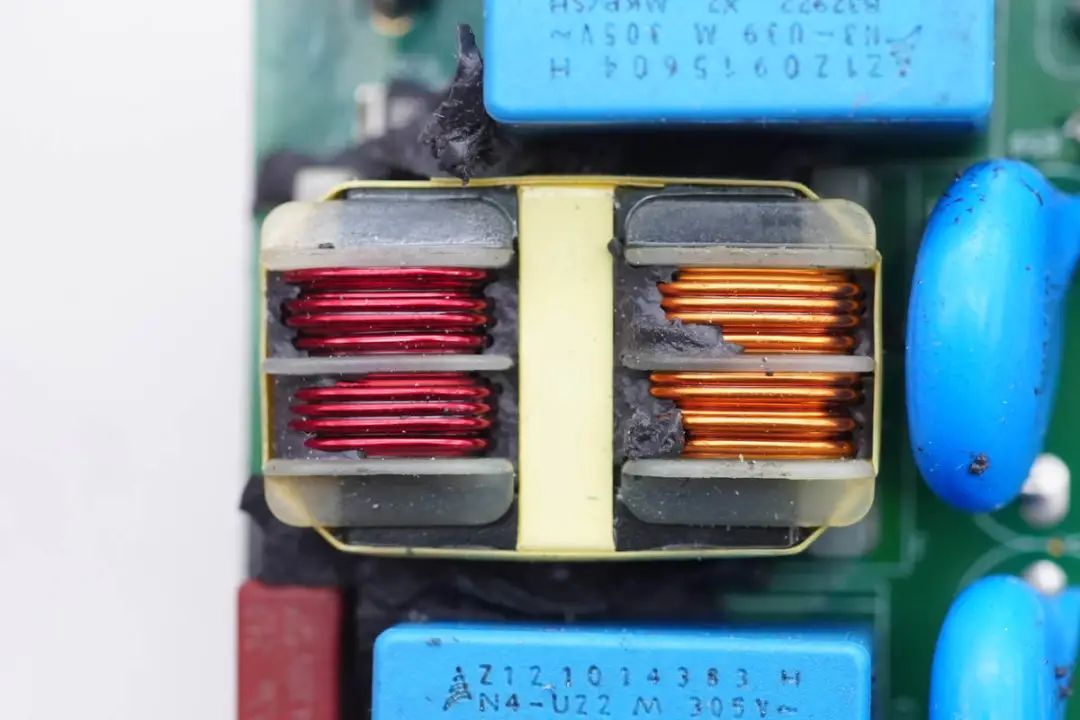

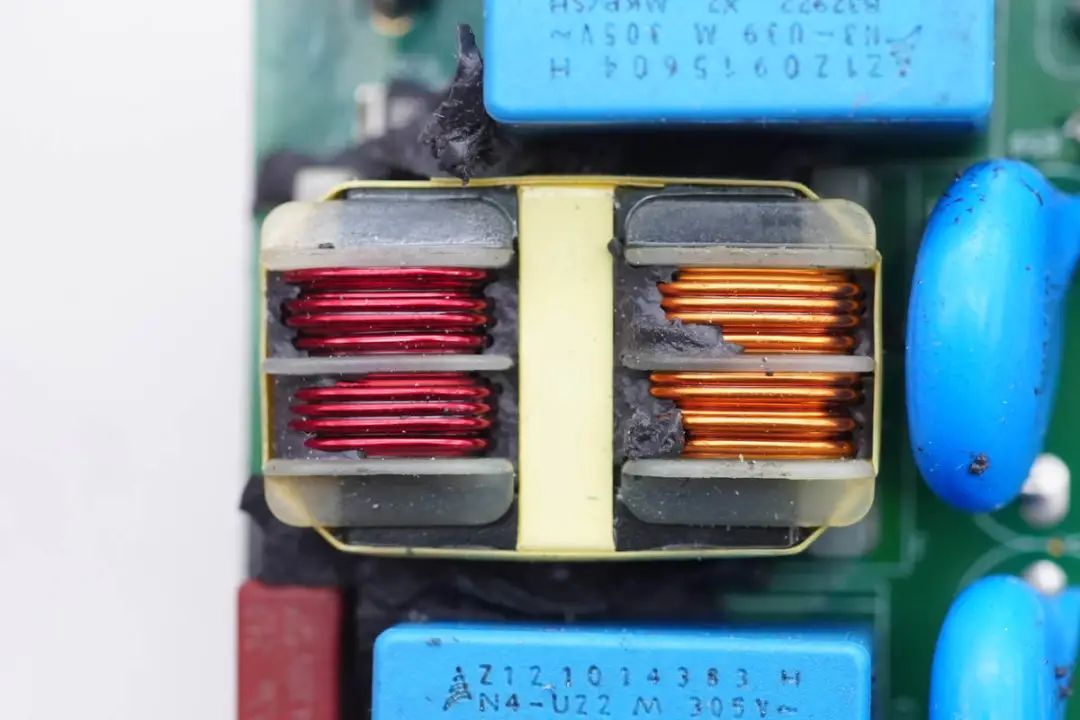

Common mode inductors are wound with red and copper-colored enameled wire and insulated with tape.

Another X2 capacitor.

Two blue Y capacitors.

Another common mode inductor.

The output fuse is from Littelfuse, with a rating of 3.15A 300V.

Another X2 capacitor.

A close-up of the discharge diode for overvoltage protection.

A close-up of the output terminal varistor from Littelfuse.

With the disassembly complete, here's a family photo of the components.

Conclusion from the Disassembly by Charging Head Network

Solar power generation is becoming increasingly integrated into our daily lives, with solar panels now capable of delivering hundreds of watts of output power. They support foldable storage for convenient outdoor use, providing power for charging devices and meeting the needs of the average user. This microinverter from ENPHASE supports solar power supply, converting it into 220Vac output and feeding it into the grid, reducing the grid's load.

Through the disassembly conducted by Charging Head Network, it is evident that this microinverter by ENPHASE is designed for outdoor applications. It features a plastic casing with internal sealing and adhesive, offering excellent weather resistance. The internal PCB incorporates thermal compound and heat sinks at the locations of power transistors to enhance heat dissipation. The inverter employs a customized main control chip, MPS drivers in the boost stage in conjunction with AOS switching transistors, and Infineon modulation drivers with their respective switching transistors. All the materials used are from top-tier brands, and when combined with the sealing process, they meet the rigorous requirements for outdoor use.