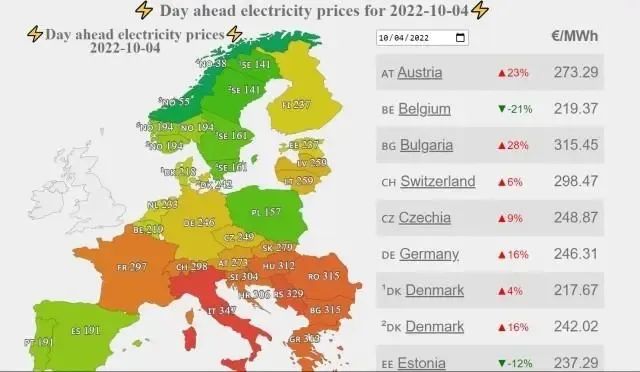

The in-car camera market has experienced rapid growth, prompting various supply chains to join, particularly the automated equipment manufacturers.

According to the Tide Power Think Tank's research, the global shipment of in-car cameras is expected to surpass the 300 million mark this year. In the evolution from L2 to L4 in autonomous driving, visual perception has become the core driving force. The in-car camera market is projected to maintain an annual growth rate of over 35% for the next five years.

As an inherently secure product, in-car cameras possess higher reliability and stability. Consequently, there is an increasing demand and reliance on these products within the automated production equipment industry.

During the module packaging process of in-car cameras, errors from multiple assemblies could escalate resulting in significant product issues. Traditional threaded compound lenses are unable to adjust for these errors, potentially leading to image misalignment and discrepancies in clarity across different areas.

Active Alignment (AA) is used to address these issues, ensuring the relative positions of components during assembly.

In the entire process of in-car camera manufacturing, AA stands out as the most crucial aspect for quality assurance in the assembly phase.

However, the current competitive landscape in the in-car camera AA equipment industry is polarized, with domestic manufacturers in a stage of breaking through.

According to the Tide Power Think Tank's "Top 10 Global In-car Camera AA Equipment Manufacturers in 2023," seven of the positions are held by prominent Chinese manufacturers like Zhuhai Huaya Technology and Guanghaojie. Yet, the top two positions are held by foreign giants, indicating a lack of dominance at the industry's top level.

There is a breakthrough on the horizon. In this long-term incremental market, overseas leaders are facing a formidable challenge from the Chinese contingent.

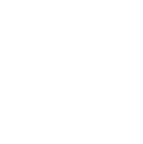

Public data reveals that the global in-car AA equipment industry leader ASMPT has experienced a significant decrease in its business revenue share in China. In 2021, it was 52%, dropping to 42% in 2022.

According to Yang S, a high-ranking executive from a leading domestic automation company, "Compared to foreign companies, Chinese domestic enterprises have multi-dimensional competitive advantages in terms of pricing, service, and delivery. The most critical aspect is that in terms of the equipment's algorithms and precision, we are already capable of competing against imported equipment."

In the long run, following Europe, America, Japan, and Korea, the new era of automobiles will undoubtedly belong to China, with the most comprehensive and compatible visual industry chain also set to emerge in China. This includes in-car AA equipment manufacturers who are witnessing comprehensive business opportunities brought by domestic replacements.

Our Authors

We have experienced employees who choose the services we provide, and our services are all professional. If you contact us, we may receive a commission.

Why You Can Trust ELECTREND

15

Years of service experience

580+

Brand Customer Choice

1000+

The choice of corporate customers