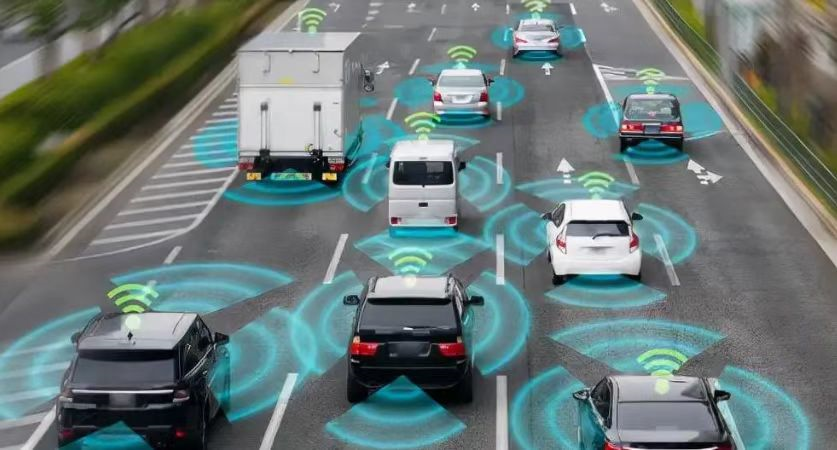

Artificial intelligence, 5G, new materials and other technologies and robotics are accelerating their integration, and the scale of the robotics industry has been able to grow rapidly.

In the Ministry of Industry and Information Technology recently held a press conference on the theme of "vigorously developing high-end equipment manufacturing", Guo Shougang, deputy director of the Department of Equipment Industry of the Ministry of Industry and Information Technology, said that in 2021, China's robotics industry-wide revenue exceeded 130 billion yuan. Among them, industrial robot production reached 366,000 units, a 10-fold increase over 2015, making it the world's largest industrial robot market.

It is reported that the application of industrial robots in China has covered 60 industry categories in the national economy 168 industry medium categories. 2021 China's service robot production reached 9.214 million units, up 48.9% year-on-year.

Benefiting from policy guidance and market demand, China's robotics industry is developing rapidly, with sales growth and market share continuing to increase.

According to the Robotics Branch of the China Machinery Industry Federation and the International Federation of Robotics, China's industrial robot market sold 271,000 industrial robots in 2021, up 50.1% year-on-year, with a growth rate of 30.1 percentage points faster than the previous year. Among them, 184,000 units of foreign-branded robots were sold, up 49.7% year-on-year and 26 percentage points faster than the previous year; 87,000 units of independent-branded industrial robots were sold, up 50.8% year-on-year and 38 percentage points faster than the previous year. 32% of the total sales of independent-branded robots were sold in 2021, up from the previous year.

In terms of market share, in 2021, the market share of own-brand robots in the electrical, electronic and equipment manufacturing, automobile manufacturing and metal processing industries rose, while the market share in the food manufacturing, plastics and chemical products manufacturing industries fell.

Robotics is known as the "crown jewel of the manufacturing industry", and its R&D, manufacturing and application are important symbols of a country's technological innovation and high-end manufacturing level. As for the development level of China's robot industry, Song Xiaogang, secretary-general of China Machinery Industry Federation and executive vice president and secretary-general of the robot branch, believes that China's industrial robot industry has initially formed a complete industrial chain. From key components to complete machines to integrated applications, each link as well as related components have relevant enterprises.

The coverage of industrial robot application areas of independent brands has also expanded year by year. Song Xiaogang said that the current coverage of the independent brand robots has a certain depth, especially in some segments of the obvious advantages, such as the metallurgical industry furnace robot, and furniture, ceramic sanitary ware and photovoltaic industry robots, these industries are not large, but directly related to the traditional manufacturing transformation and upgrading, quality and efficiency, and improve the environment can be successfully completed. In the future, there is still a lot of room for expansion in the range of applications.

Despite the huge progress, the domestic robotics industry still has a long way to go. Zhao Jie, director of the Robotics Research Institute at HUST, is blunt: "The domestic robotics industry is basically there except for special chips, but the industry development needs to solve the problem of fine and good."

Zhao Jie believes that the hardware part of the robot may gradually move toward standardization, modularization and even unitization in the future. The gap with the international leading level is mainly reflected in the key technologies such as robot design, structure, motion control and reliability. In particular, it should be noted that robot is a strong coupling of mechanical and electrical products, and the contribution of a single technological breakthrough to the improvement of the performance of the whole machine is limited.

How to improve the core competitiveness of domestic robots? Zhao Jie believes that it is necessary to make good use of innovation centers, engineering technology centers and state key laboratories, and use the advantages of the system to achieve systematic breakthroughs.

Song Xiaogang also said that the domestic robotics industry does have the problems of low market share and insufficient supply of high-end products. These problems are not only manifested in finished robots, but also in parts, software and other links. The main problem is insufficient R&D innovation, including insufficient innovation capacity, insufficient investment and insufficient market application.

He said that domestic robotics companies are small in volume compared to large international robotics companies and have limited investment in innovation and R&D. Through collaborative innovation with other enterprises in the industry chain, they can develop matching robot equipment according to the specific production needs of different enterprises while obtaining more R&D investment. The development of the robotics industry is driven by the application, and the machine drives the technological progress in the field of components, ultimately realizing the common improvement of the whole chain.

Guo Shougang said that the Ministry of Industry and Information Technology will actively expand industry applications, implement the "robot +" application action, organize accurate matchmaking between production and demand, accelerate the popularization of mature scenarios, increase product innovation in emerging areas, strengthen the niche areas of special applications, and help the digitalization and intelligent transformation and upgrading of various industries. At the same time, the industry backbone enterprises are encouraged to play a leading role in the field of machine, parts and system integration to build an ecology of integrated development of large and medium-sized enterprises.

According to market data, China's robot market will reach $17.4 billion in 2022, including $8.7 billion for industrial robots, $6.5 billion for service robots and $2.2 billion for special robots, with an average annual growth rate of 22% over five years.

Our Authors

We have experienced employees who choose the services we provide, and our services are all professional. If you contact us, we may receive a commission.

Why You Can Trust ELECTREND

15

Years of service experience

580+

Brand Customer Choice

1000+

The choice of corporate customers