Recently Chongqing Might Optoelectronics Co., Ltd. was established, the legal representative is Hiroshi ISHIZAKIKOKI (ISHIZAKIKOKI), the registered capital of 1 billion RMB, the business scope includes the manufacture of optoelectronic devices, sales of optoelectronic devices, technical services, technology development, import and export of goods, etc.. The company is jointly owned by BOE's wholly owned subsidiary, Beijing BOE Vision Technology Co.

This is a belated joint venture and a landmark event for Apple's supply chain to continue to move into mainland China after previous rumors that BOE may have been asked by Apple to stop supplying panels for the iPhone 13 because it changed the panel design, indicating that Apple and Apple supply chain companies still have some confidence in the security of the supply chain in mainland China.

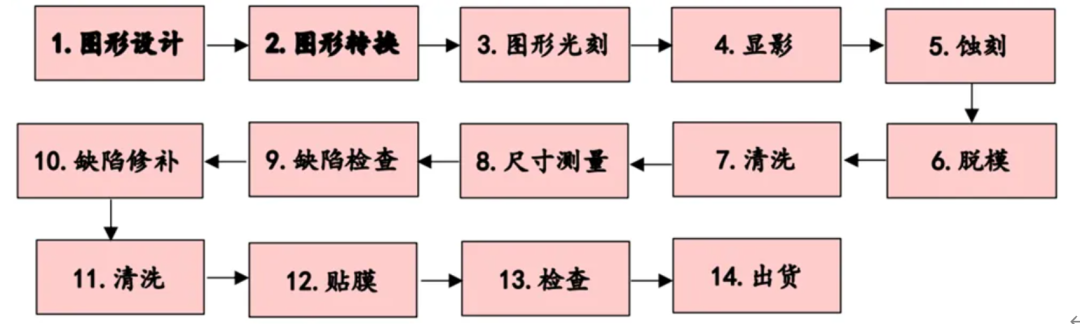

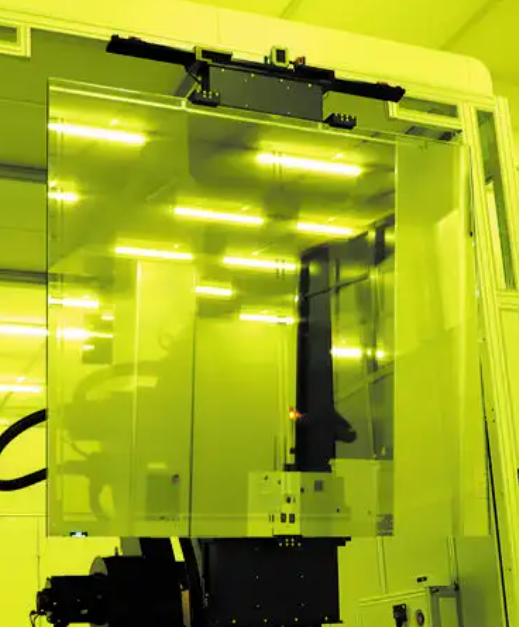

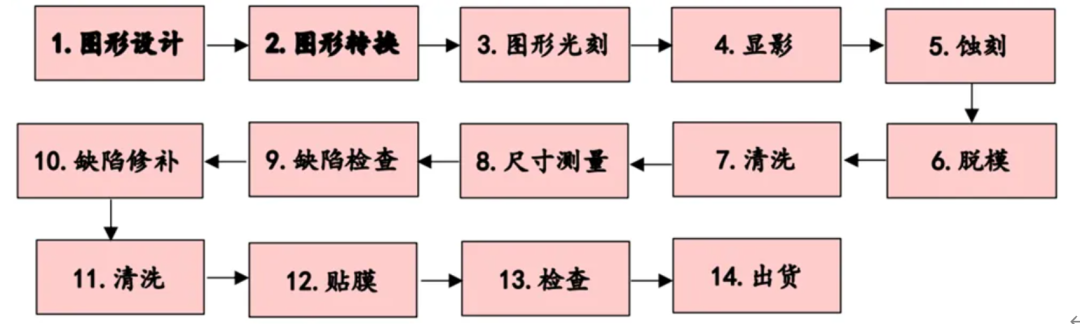

In fact as early as October 22nd last year, TAG Heuer announced that it had signed a contract with Beijing BOE Vision Technology Co. to establish a joint venture subsidiary in China. The new joint venture will be centered on TAG Heuer's Flat Panel Display Division, which will be used to manufacture and sell photomasks that are essential in the production of LCD/OLED displays for TVs, smartphones and computers.

Founded in 1941, Hoya Corporation is a global manufacturer of optical instruments and medical technology company and a leading supplier of innovative high-tech and medical products.Hoya is active in the healthcare and information technology sectors, providing eyeglasses, medical endoscopes, IOLs, optical lenses and key components for semiconductor devices, LCD panels and HDDs. Hoya is well known as the leading Japanese lens brand, with a market share of nearly 50% in Japan, where it has always been the number one, as well as being firmly in the forefront of the global resin lens segment. Of course, TAG Heuer has been supplying JDI since the LCD era, and is a long-time supplier of display panel backplane circuit mask to Apple.

The establishment of the joint venture also means that BOE will "officially" adopt the international display panel backplane design and supply chain management model.

Previously, TheElec reported that BOE changed the circuit width of thin-film transistor (TFT) on its iPhone 13, and was discovered by Apple in February 2022, and Apple asked to stop production. And the TFT circuit width change, certainly go through the mask board suppliers to confirm and review the link, whether TAG Heuer is also involved is unknown, but certainly the details of the joint venture company landed in Chongqing should have some impact, making the Mighty Optoelectronics in a year later to be established.

After Apple's self-research high PPI retina display, has been using its own unique TFT backplane drive line design and algorithm, and quickly iterate to touch integrated backplane design, low-power power management and other analog-digital hybrid design approach, the subsequent Apple R & D fingerprint identification line and later cut into the field of chip design have had a greater impact.

At the same time, Apple has its own special tuning method in all circuit designs involving optical circuits, so it is often difficult for other panel manufacturers to understand Apple's line design intentions, and in the imitation process without Apple's real algorithm, just applying Apple's test procedures for equipment suppliers, it is often difficult to restore the actual display effect of Apple's certified products.

And as mentioned before, Apple is actually a relatively "lazy" enterprise, often in their own design architecture after the completion of the closure, just ask suppliers to adjust their equipment calibration and quality specifications in accordance with the existing production line process parameters, unless it will have a significant increase in production line yields, otherwise Apple basically "Apple does not bother with process improvement measures.

In fact, this is also the inevitable result of Apple mainly pushing a small number of explosive products, because no matter what kind of product design, as long as the design in accordance with the technical capabilities provided by the supplier, the initial mass production verification is no problem, basically can be optimized through a large number of manufacturing process equipment, materials and testing means to achieve the lowest cost of mass production.

In the panel manufacturing process, the backplane line manufacturing accounts for a large part of the process, in the entire production process of mass production is not difficult, but the impact on the yield is greater, so the ordinary panel factory in order to improve the yield, it is easy to brainstorm on the backplane line design. Especially in mainland China panel companies, "process innovation" through the design of the mask version to reduce costs and improve yields, almost the entire engineering department is one of the "daily work".

And in mainland China, mask plate suppliers, like other supply chain companies, provide panel companies with "new" materials, technologies, processes or "industry secrets" from time to time, and guide customers to update mask plates from time to time to improve "Performance", almost is also the industry open "practice".

The establishment and operation of Mighty Optoelectronics at least locks the relationship between BOE and HOYA, no matter from the technical level, or quality and cost level, so that both sides are on the same front.

Our Authors

We have experienced employees who choose the services we provide, and our services are all professional. If you contact us, we may receive a commission.

Why You Can Trust ELECTREND

15

Years of service experience

580+

Brand Customer Choice

1000+

The choice of corporate customers