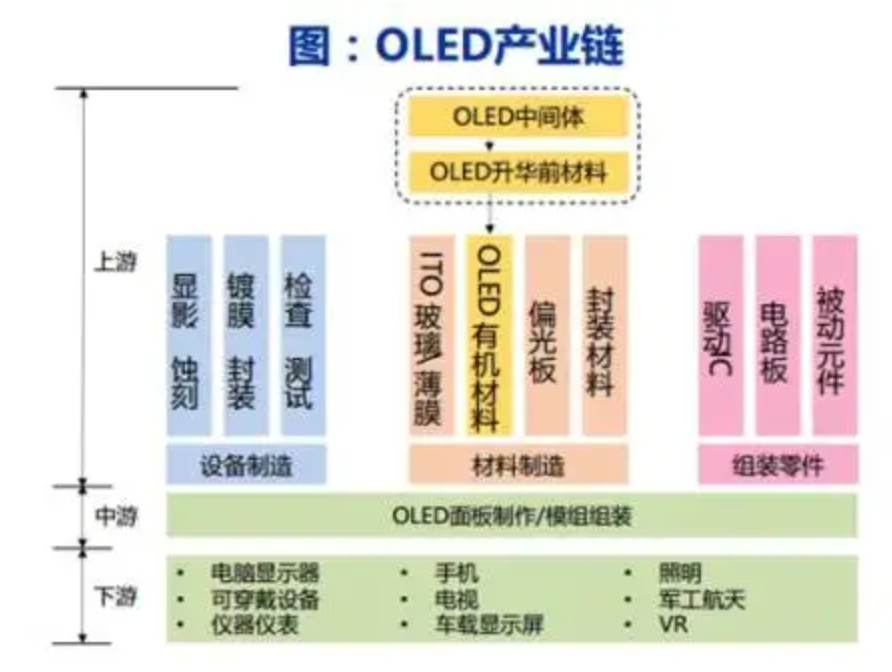

Recently, the industry chain news shows that Apple is dissatisfied with LGD in the iPhone OLED panel frequent conditions, coupled with the Japanese evaporation machine manufacturers on LGD cooperation in the development of 8.7 generation OLED panel equipment costs dissatisfaction, as well as the Chinese mainland government and Apple and Japanese equipment manufacturers investment commitments and other multiple factors, Apple suspected that the iPad OLED production line planning to make Adjustment.

The news shows that in addition to the original Samsung display routine in the production of iPadOLED panel on the 6th generation line, and pre-investment in a vertical vapor deposition 8.7 generation OLED panel production line to cooperate in the development of new processes, the original plan by LGD to build a Japanese plating equipment factory and Apple display R & D team to jointly develop the 8.7 generation OLED panel production line, will be re-sited planning.

Samsung display, LGD last year in the investment planning note, have the core customer plans to launch the first OLED display tablet computer information in 2024, it is widely believed that the core customer is Apple.

Apple's display R & D team is currently two panel manufacturers in South Korea to develop a new LTPO low-power OLED panel for tablet PCs and IT display applications, including the direct use of glass substrates for mass production, but the encapsulation process is the use of direct inkjet printing of plastic resin encapsulation process, known to the outside world as a combination of soft and hard hybrid substrate OLED process. The new process that can reduce the difficulty and cost of mass production of OLED panels, but also to maintain a better high-definition display characteristics, but also to reduce weight.

In addition, this OLED product is also based on LGD's automotive OLED lamp mass production process, using a double-layer series-parallel driving method to adjust the display brightness, energy saving, and improve the life of OLED devices.

As the complexity of the mass production process of this product is actually not high, and the use of glass substrates after the difficulty of the evaporation process has been significantly reduced, so the panel factory and Apple want the product can be in the 8.7 generation OLED panel production line for more economical production.

At present, high generation OLED vapor deposition equipment technology is basically in the hands of Japanese and South Korean manufacturers, are using horizontal vapor deposition method, it is difficult to overcome the FMM metal mask plate high temperature, gravity deformation problem. However, the original vertical vapor deposition program mastered by the U.S. manufacturers can more easily solve the problem of deformation in the production line of high generation OLED panels, but in the vapor deposition material and vapor deposition process adaptation, has not found a suitable solution.

Samsung Display has rich mass production technology and experience in horizontal evaporation OLED panel process, so in large size OLED panel, it has been hoping to overcome the problem of FMM metal mask plate deformation through a new process, so that it can produce large size RGB OLED panel with real HD display.

Samsung Display has been actively seeking cooperation in the U.S., Japan, and Korea this year in the hope of practicalizing the vertical evaporation OLED panel technology in the three places, including equipment, OLED light-emitting materials, and FMM mask board design.

At present, Apple's technical team has basically identified the OLED light-emitting materials used in the laminated light-emitting technology, whether it can meet the needs of Samsung Display proposed vertical evaporation equipment, but also wait for the equipment to come out to verify, so Apple hopes that Samsung Display can verify and mass produce iPad OLED panels for Apple on the current glass substrate OLED production line.

In addition, LGD and Apple's planning is directly by the Japanese evaporation equipment manufacturers to develop 8.7 generation OLED panel line equipment, and then by LGD to organize mass production capacity direct production. LGD also said it will choose the opportunity to invest in the construction of this panel line, in order to get more OLED panel orders from Apple.

But LGD's internal disagreement over the line, one is the line of capital expenditure is huge, the economic downturn LGD is difficult to bear such a huge investment risk. Secondly, LGD's current OLED product line is more, it is difficult to provide sufficient human resources to cooperate with Apple to debug the 8.7 generation OLED panel production line in a short period of time.

Of course, there is an important reason, is that Apple and LGD together to build the iPhone OLED panel production line, has been a continuous loss for many years, and did not bring real revenue for LGD. LGD's own transparent OLED panels and automotive OLED panels are in the actual state of profitability, LGD internal believe that it is more important to enhance LGD's own core competitiveness, rather than just with Apple a customer sprint production capacity to accompany the OLED track.

Unlike LGD's hesitation, BOE, a panel maker in mainland China, has shown more enthusiasm to cooperate with Apple. Apple's resident team in BOE also handed over the mass production process package of OLED panels developed in Korea to BOE for mass production verification, so BOE has almost synchronized with Samsung Display and LGD to test produce the OLED panels with stacked light-emitting technology of medium and large sizes that Apple needs. .

For Apple's new 8.7 generation OLED panel production line, BOE also has a very strong interest, BOE also repeatedly and Japanese evaporation equipment manufacturers to discuss cooperation in the development of 8.7 generation OLED panel production line evaporation equipment. Different from LGD's cooperation, BOE also said that it can bear part of the preliminary research and development costs.

In addition, when the government of mainland China coordinates with Apple's supply chain team on production capacity and market quota, it also actively seeks for Apple to land the relevant production capacity that can be supported in mainland China, so as to enhance the supporting capacity in mainland China and reduce the management cost of the supply chain.

In the new 8.7 generation OLED panel line investment, the Chinese mainland government also put forward more favorable conditions for Apple, such as Apple does not have to take the same as the two Korean panel manufacturers, but also need Apple's own advance part of the funds to invest in the construction of production lines, the Chinese mainland government is willing to solve all the investment funds to build capacity to meet Apple's needs.

Most of the current panel industry construction investment is pulled by the Chinese mainland panel manufacturers, so Apple's new 8.7 generation OLED panel line investment planning changes, the future panel equipment manufacturers have a greater impact on the business focus. At present, the global economy is not very good, equipment manufacturers are also more cautious in their input capital expenditure. But compared with the global market, mainland China in the panel investment more generous, so equipment manufacturers are also interested in lobbying Apple to the new 8.7 generation OLED panel production line investment part to mainland China to invest in construction.

Looking ahead to the next few years, the panel factory equipment procurement is also almost concentrated in mainland China, in addition to Apple's 8.7 generation OLED panel production line, the main procurement equipment production line including TM18-2 line and TM19 and TCL Huaxing's T9-2. And the original preparation for the construction of a BOE 6 generation AMOLED production line, the Chinese mainland government hopes that BOE put on hold to invest in the integration of mainland China All the 6 generation AMOLED production line in mainland China to unify the operation to solve the BOE's subsequent capacity planning needs.

In this way, BOE basically has no new capital expenditure demand on equipment, and BOE has more resources to ensure the construction and implementation of Apple's 8.7 generation OLED panel line.

At present, in addition to LGD expressly postponed the construction of 8.7 generation OLED panel production line, Samsung Display said it will accelerate the progress of its 8.7 generation OLED panel production line, while Apple and BOE in the cooperation of the new production line, has not been officially stated.

Translated with www.DeepL.com/Translator (free version)